Xsens Redefines Marine Stability with Centimeter-Accurate Heave Sensor

- Heave Accuracy: Less than 5 cm for wave periods up to 29 seconds, approximately 6 cm for periods up to 40 seconds

- Output Rate: Up to 100Hz, suitable for demanding active heave compensation (AHC) systems

- Upgrade Method: Firmware update, no hardware modifications required for existing Xsens Sirius and Avior units

Experts in marine technology are likely to view this firmware upgrade as a significant advancement, offering centimeter-level heave accuracy in a compact, cost-effective form factor that could broaden access to high-precision motion compensation across the maritime industry.

Xsens Redefines Marine Stability with Centimeter-Accurate Heave Sensor

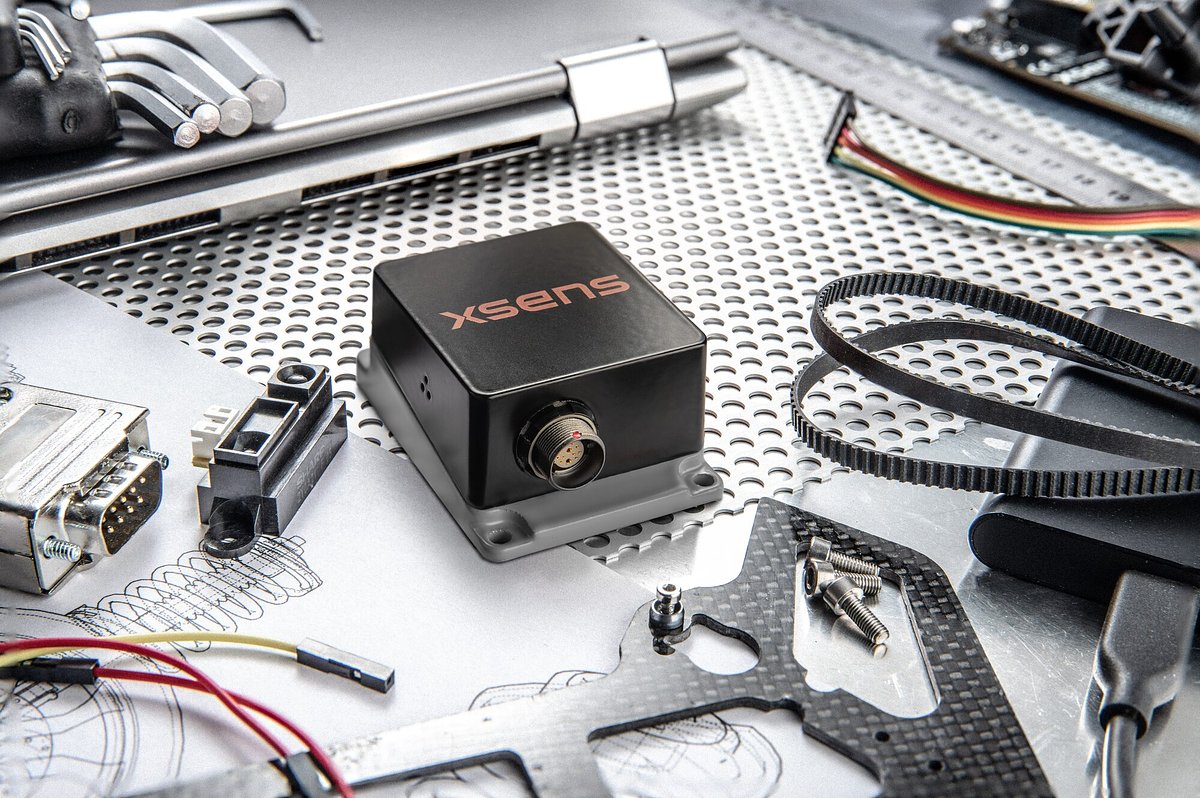

ENSCHEDE, Netherlands – January 13, 2026 – In a significant move for the marine technology sector, Xsens today announced a powerful firmware upgrade for its industrial-grade inertial measurement units (IMUs), introducing a feature that delivers centimeter-level accuracy for vertical motion. The new 'Heave' capability, now available for the Xsens Sirius and Xsens Avior sensors, provides real-time vertical displacement data with a precision of less than five centimeters, aiming to set a new standard for wave motion compensation and stabilization systems across a wide array of maritime applications.

This development addresses a critical challenge in marine operations: accurately measuring and compensating for the constant vertical movement of a vessel or platform caused by waves. By providing a complete, high-fidelity motion profile - including roll, pitch, yaw, and now heave - directly from a single, compact sensor, the company is positioning its technology as a streamlined alternative to larger, more complex, and often more expensive tactical-grade motion reference units (MRUs).

A New Benchmark for Motion Sensing

For marine engineers and operators, heave is the relentless enemy of precision. Whether landing a multi-ton module on a subsea structure, deploying a sensitive instrument, or ensuring a hydrographic survey produces clean data, an uncompensated vertical motion can lead to equipment damage, operational delays, and compromised safety. Traditionally, achieving the necessary compensation required either bulky, high-cost MRUs or complex systems that relied on external processing to calculate heave from raw sensor data.

This upgrade changes that paradigm by performing all calculations directly on the sensor itself. The new algorithm provides real-time heave accuracy better than 5 cm for wave periods up to 29 seconds, a range that covers the majority of conditions encountered in marine applications. For longer, more challenging swell periods of up to 40 seconds, the accuracy remains at approximately 6 cm, which Xsens notes is double the range supported by comparable industrial-grade sensors. With an output rate of up to 100Hz, the data is fast enough for the most demanding active heave compensation (AHC) systems used in offshore cranes and winches.

"Engineers now get vertical displacement data directly onboard, alongside roll, pitch, and yaw," said Ayush Sharma, Algorithms Engineer at Movella, Xsens' parent company. "This gives marine customers the complete motion reference they need for stabilization and compensation systems, without the size or certification overhead of tactical MRUs."

The underlying technology uses proprietary phase correction and bias estimation algorithms designed to mitigate the cumulative error, or drift, that can plague inertial sensors over long operational periods. This ensures that the accuracy is maintained throughout extended missions. Furthermore, the system allows users to define specific offset points - a Center of Rotation (COR) and a Point of Interest (POI) - so that the heave measurement accurately reflects the motion of a specific piece of equipment, like a crane tip or sonar head, even if the sensor is mounted elsewhere on the vessel.

Unlocking Efficiency and Safety Across the Seas

The impact of this enhanced precision is expected to be felt across the entire maritime industry. In the high-stakes world of offshore oil, gas, and wind, active heave compensation on cranes is non-negotiable for safe and efficient subsea construction and maintenance. By providing a cost-effective and compact solution, this technology could accelerate the adoption of advanced AHC systems on a wider range of vessels and platforms.

For the rapidly growing field of marine robotics, the benefits are equally compelling. Autonomous Underwater Vehicles (AUVs) and Remotely Operated Vehicles (ROVs) rely on precise motion data for navigation, station-keeping, and delicate manipulation tasks. A compact, all-in-one sensor that delivers high-fidelity heave data simplifies vehicle design, reduces payload, and improves the quality of data collected during subsea inspections, mapping, and docking procedures.

Hydrographic surveying is another key application. Accurate heave compensation is vital for removing wave-induced errors from multibeam sonar data, which is essential for creating detailed and reliable seabed maps. The ability to achieve this level of precision from an industrial-grade IMU reduces reliance on complex GNSS/RTK systems and simplifies the setup for survey vessels, potentially lowering costs and increasing operational flexibility.

The Competitive Tide and Strategic Direction

Xsens is entering a competitive but evolving market. Established players like Kongsberg Discovery, with its well-regarded MRU H, and SBG Systems, which also offers solutions with 4-5 cm real-time heave accuracy, have long served the high-end marine market. These companies are known for their robust, highly-certified systems designed for the most demanding environments.

However, Xsens' strategy appears to be focused on democratizing access to this level of precision. By delivering tactical-grade performance in an industrial-grade form factor, Movella is targeting a broader segment of the market that includes smaller autonomous vessels, cost-sensitive commercial operations, and scalable robotic fleets where size, weight, power, and cost (SWaP-C) are critical design constraints. This move aligns perfectly with Movella's overarching strategy to embed its sensor technology as a core component within the growing Automation & Mobility sector, treating the marine environment as a key frontier for autonomous systems.

Seamless Integration and Robust Design

Perhaps one of the most significant aspects of the announcement is the ease of adoption. The new heave feature is being rolled out as a firmware update, meaning the global fleet of existing Xsens Sirius and Avior units can be upgraded without any hardware modifications or recalls. For system integrators and existing customers, this represents a substantial capability boost with minimal implementation cost or downtime. New units will ship with the feature pre-installed, enabled via a simple software setting.

To meet diverse integration needs, the technology is offered in two distinct packages. The Xsens Sirius is a standalone unit housed in a rugged, IP68-rated enclosure designed for harsh deck and subsea environments, and it meets MIL-STD-202 for shock and vibration. The Xsens Avior is a more compact, board-level OEM module designed for deep integration into custom hardware designs.

Both products support a range of industry-standard communication interfaces, including RS-422, CAN, and UART. To further simplify development, Xsens provides a comprehensive and free Software Development Kit (SDK) with support for C/C++, Python, ROS1, ROS2, and MATLAB, ensuring engineers can quickly prototype and deploy their applications. The units are available globally and are ITAR-free, simplifying international distribution and collaboration. This focus on a robust developer ecosystem and straightforward integration pathways is critical for enabling the next wave of innovation in marine technology.

📝 This article is still being updated

Are you a relevant expert who could contribute your opinion or insights to this article? We'd love to hear from you. We will give you full credit for your contribution.

Contribute Your Expertise →