Tiny Capacitor, Big Impact: Taiyo Yuden Shrinks Power Delivery for the AI Era

A new, ultra-compact capacitor from Taiyo Yuden promises to boost performance & efficiency in AI servers, tackling component shortages & driving a greener data center future.

Tiny Capacitor, Big Impact: Taiyo Yuden Shrinks Power Delivery for the AI Era

By David Patterson, Industrial Innovation: Tech, Trends & Transformation

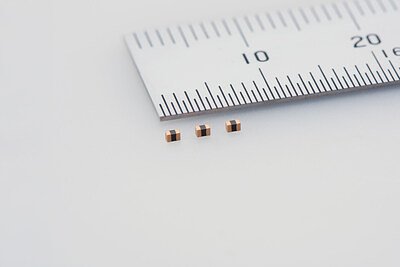

Tokyo, Japan – The relentless demand for more powerful and efficient computing is driving innovation at the component level, and Taiyo Yuden is leading the charge with a breakthrough in capacitor technology. The company has commercialized an embeddable multilayer ceramic capacitor (MLCC) boasting an impressive 22µF of capacitance within a remarkably small 1005M size (1.0 x 0.5mm). While seemingly incremental, this innovation addresses a critical bottleneck in modern electronics, particularly in the rapidly expanding world of artificial intelligence.

This isn’t just about shrinking components; it’s about fundamentally changing how power is delivered within high-performance systems. “The trend towards miniaturization isn’t just a desire; it’s a necessity,” explains one industry analyst. “As AI models grow in complexity, the demand for denser computing architectures increases, and that requires components that can deliver power efficiently in a limited space.”

Addressing the Power Bottleneck in AI Servers

The core challenge lies in the power delivery network (PDN) within AI servers. These systems, packed with power-hungry GPUs and other specialized processors, require stable and efficient power distribution to prevent performance degradation and ensure reliable operation. Decoupling capacitors, positioned close to the processors, act as local energy reservoirs, filtering out noise and providing the instantaneous current needed for peak performance.

Traditionally, achieving high capacitance in a small form factor has been a significant hurdle. “Increasing capacitance usually means increasing the size of the capacitor,” notes a materials scientist specializing in ceramic components. “Taiyo Yuden’s breakthrough lies in their enhanced external electrode formation technology, which allows them to pack more dielectric material into a smaller space.”

This innovation isn’t merely a technological feat; it's a strategic move to address critical industry pain points. The global component supply chain has been plagued by shortages in recent years, impacting everything from automotive production to data center expansion. By offering a smaller, high-performance capacitor, Taiyo Yuden helps system designers optimize board space and potentially reduce their reliance on larger, less readily available components.

Competition & Market Positioning

Taiyo Yuden isn’t operating in a vacuum. The MLCC market is fiercely competitive, with players like Murata, Samsung Electro-Mechanics, and KEMET vying for market share. Murata, currently the market leader with around 35% share, offers high-capacitance options, but none currently match Taiyo Yuden’s 22µF in the 1005M size. Samsung Electro-Mechanics, known for its reliability in automotive and industrial applications, offers similar capabilities, but trails behind in overall capacitance in this footprint.

“Taiyo Yuden’s strength lies in its ability to innovate at the materials science level,” says an embedded systems engineer familiar with the company’s products. “They consistently push the boundaries of what’s possible in terms of miniaturization and performance.”

However, the company faces challenges in scaling production to meet potential demand. While TDK, Taiyo Yuden’s parent company, possesses a robust global manufacturing footprint, ramping up production requires significant investment and careful planning. The company must also balance cost competitiveness with maintaining its reputation for high-quality components.

Beyond AI: Broader Implications

The impact of this innovation extends beyond AI servers. The demand for smaller, more efficient components is growing across a wide range of industries, including automotive, industrial automation, and consumer electronics. Electric vehicles, for example, require high-performance power electronics, and smaller capacitors can help reduce the size and weight of battery management systems.

Moreover, this technology contributes to a more sustainable future. By improving power efficiency, it reduces energy consumption and lowers the carbon footprint of data centers and other electronic systems. “The trend towards green computing is driving demand for components that can help reduce energy waste,” explains a sustainability consultant specializing in the tech industry. “Smaller, more efficient capacitors are a key part of that equation.”

Looking Ahead

Taiyo Yuden’s new MLCC represents a significant step forward in component technology. While challenges remain in terms of scalability and competition, the company is well-positioned to capitalize on the growing demand for smaller, more efficient electronic components. The convergence of artificial intelligence, green computing, and the relentless pursuit of miniaturization is creating a fertile ground for innovation, and Taiyo Yuden appears poised to remain a leading force in shaping the future of electronics.

The company’s success will depend on its ability to continue pushing the boundaries of materials science, optimizing its manufacturing processes, and adapting to the evolving needs of its customers. However, with its strong technical expertise and commitment to innovation, Taiyo Yuden is well-equipped to meet the challenges ahead and deliver on its promise of a more efficient and sustainable future.