Harpak-ULMA System Shatters Meat Packaging Speed Limits with Magnets

- 200 ppm: Harpak-ULMA's magnetic transport system achieves speeds as high as 200 packs per minute, nearly doubling the industry standard of 120 ppm.

- 100% throughput increase: The system offers a fundamental re-engineering of the tray-sealing process, delivering a near 100% increase in packaging throughput.

- 14-up sealing array: The integrated system includes a massive 14-up sealing array to achieve its remarkable speeds.

Experts in the food processing sector would likely conclude that Harpak-ULMA's magnetic transport system represents a transformative advancement in meat packaging technology, setting a new industry benchmark for speed, efficiency, and operational reliability.

Harpak-ULMA's Magnetic Transport System Shatters Meat Packaging Speed Limits

TAUNTON, MA – January 20, 2026 – In a move poised to redefine efficiency in the food processing sector, Harpak-ULMA has unveiled a groundbreaking tray-sealing application for high-volume ground-meat production. The new solution, powered by the G. Mondini Trave Sinfonia® platform, leverages a sophisticated magnetic transport system to nearly double packaging throughput, establishing a new performance ceiling in an industry grappling with labor scarcity and intense pressure to optimize output.

For years, the mechanical limitations of conventional packaging lines have capped speeds for ground meat at around 120 packs per minute (ppm). Harpak-ULMA's innovation shatters that barrier, achieving speeds as high as 200 ppm. This leap forward is not an incremental improvement but a fundamental re-engineering of the tray-sealing process, promising to deliver significant economic and operational advantages to meat processors.

A New Benchmark in Packaging Speed

The core of this advancement lies in the Sinfonia’s software-controlled magnetic transport architecture. Instead of relying on traditional belts, chains, and pusher arms, the system propels trays on independent magnetic shuttles, or “Nests,” with micron-level accuracy. This design effectively eliminates the friction and mechanical bottlenecks that have historically constrained speed, especially in delicate low-oxygen Modified Atmosphere Packaging (MAP) applications common for fresh meat.

“The competitive ceiling for grind-line tray sealing is around 120 ppm. With Sinfonia, we can engineer a 200-ppm grind line—almost a 100% throughput increase,” stated Carlo Bergonzi, Tray Sealing Product Manager at Harpak-ULMA. “Sinfonia fundamentally changes what's possible in ground-meat tray-sealed packaging.”

This technology, which functions like a high-speed, high-precision linear motor system, gives processors independent control over each tray’s movement. Shuttles can accelerate and decelerate rapidly, allowing each station in the packaging line—from portioning and denesting to loading and sealing—to operate at its own optimal rate. This is a stark contrast to conventional systems where the entire line is tethered to the fixed, uniform pace of a mechanical conveyor. The result is a faster, more stable, and significantly cleaner process.

While other high-performance systems exist, they often fall short of this new benchmark. For example, leading stretch overwrappers typically top out around 120 ppm, while high-capacity inline tray sealers for vacuum gas applications might reach 84 ppm. The Sinfonia’s claimed 200 ppm capability positions it in a class of its own for grind-line applications.

Automation as an Antidote to Industry Headwinds

The launch arrives at a critical time for the meat and poultry industry, which continues to face persistent labor shortages. The physically demanding nature of work in processing plants has made it difficult to attract and retain staff, forcing companies to seek solutions that reduce their reliance on manual labor. The Sinfonia’s fully automated system directly addresses this challenge by minimizing the need for human intervention in the packaging process.

Beyond solving labor issues, the system’s design delivers substantial operational benefits that contribute to a lower total cost of ownership. The magnetic transport architecture contains far fewer moving parts than its mechanical counterparts. The absence of belts, gears, and bearings reduces wear and tear, leading to significantly lower maintenance requirements, less downtime, and higher Overall Equipment Effectiveness (OEE). Changeovers between different tray sizes or product formats are also simplified and accelerated through software-based controls, maximizing production uptime.

Furthermore, the technology offers a major step forward in food safety and hygiene. Traditional belt-driven systems can be a source of contamination and are often difficult to clean thoroughly. By eliminating these components, the Sinfonia creates a cleaner tray path, reducing the risk of microbial growth and product contamination. This enhanced sanitation is a critical advantage in an industry where food safety is paramount.

Engineering for Modern Market Demands

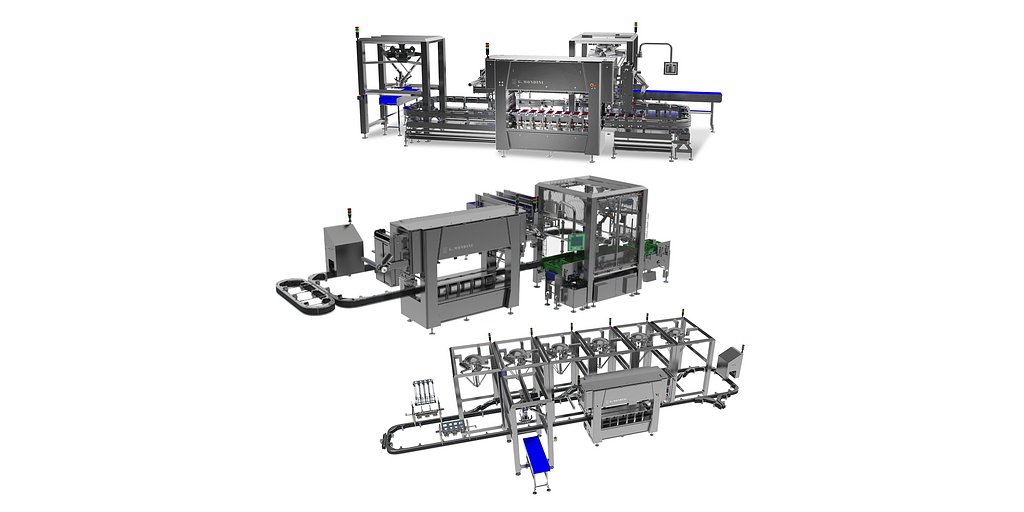

This new application of the Sinfonia platform, first introduced in 2023, has been specifically configured for the unique challenges of ground-meat production. It seamlessly integrates portioning, dual denesting, retractable conveyor loading, and a massive 14-up sealing array to achieve its remarkable speeds. This integrated approach ensures a consistent and contamination-resistant process from start to finish.

The timing aligns perfectly with evolving consumer and retailer demands, particularly the growing popularity of case-ready “meat-brick” formats. These tightly sealed, rectangular packages require exceptional process control to maintain their shape and quality. The Sinfonia's ability to handle each tray independently ensures the stability and precision needed for these challenging formats.

“By controlling each tray independently, we remove the mechanical constraints that typically dictate line speed,” Bergonzi added. “The result is a faster, cleaner, and far more stable tray-sealing process that simply isn't achievable with conventional systems. Given the momentum behind meat-brick formats across major retailers, this application directly addresses the performance conversations we’re hearing from processors as they head into IPPE 2026.”

Harpak-ULMA, the North American arm of the billion-dollar Spanish packaging giant ULMA, plans to showcase the technology at the International Production & Processing Expo (IPPE) in Atlanta in January 2026. The event will provide meat processors a firsthand look at a technology that not only promises to boost their bottom line but may also set the operational standard for the entire industry for years to come.