Diamond Quanta's New Tech Aims to Cool Overheating AI Superchips

- Diamond has five times the thermal conductivity of copper, making it a superior material for cooling advanced semiconductor chips. - Over half of all electronic failures are attributed to heat-related issues, posing a significant challenge to the industry. - Diamond Quanta's Adamantine Thermal™ platform is designed for wafer-to-wafer (W2W) and chip-to-wafer (C2W) bonding, ensuring seamless integration into existing semiconductor manufacturing workflows.

Experts agree that Diamond Quanta's engineered-diamond platform represents a critical breakthrough in thermal management for next-generation electronics, addressing a growing bottleneck in the semiconductor industry.

The Diamond Age of Computing: Cooling the Next Generation of Chips

MOUNTAIN VIEW, CA – January 19, 2026 – As the relentless demand for artificial intelligence and high-performance computing pushes modern electronics to their breaking point, a Silicon Valley startup is looking to the world’s hardest material for a solution. Diamond Quanta today announced Adamantine Thermal™, an engineered-diamond platform designed to solve the critical overheating problem plaguing the semiconductor industry.

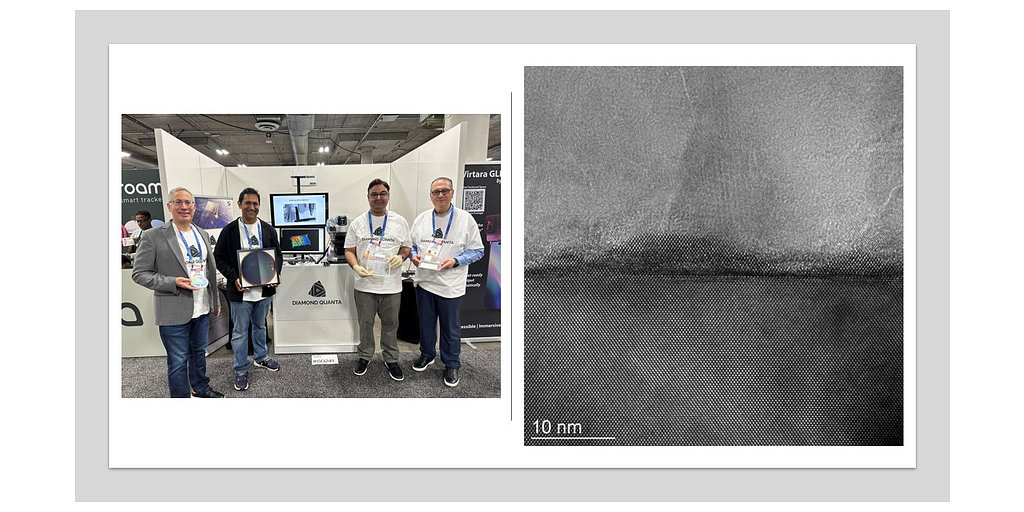

The announcement, which builds on the company's promising debut at CES 2026, introduces a novel way to integrate diamond—a material with five times the thermal conductivity of copper—directly into advanced semiconductor packaging. This innovation aims to transform diamond from a niche, exotic material into a foundational component for next-generation electronics, potentially unlocking new levels of performance and reliability.

The Unbreakable Bottleneck: Heat in Modern Electronics

For decades, the semiconductor industry has been governed by Moore's Law, the steady march toward smaller, faster, and more powerful chips. But that progress has come at a cost: heat. With billions of transistors packed into ever-shrinking spaces, modern processors, especially those powering AI data centers, generate thermal loads that are becoming unmanageable. More than half of all electronic failures are directly attributable to heat-related issues, a problem that threatens to stall innovation.

"The industry is hitting a thermal wall," noted one analyst from a leading technology research firm. "Conventional cooling methods are no longer sufficient for the power densities we're seeing with chiplet architectures and 3D-stacked systems. Without a breakthrough in materials, we risk throttling the very progress we aim to achieve."

This challenge is particularly acute in the realm of advanced packaging, where heterogeneous integration—the mixing and matching of different chiplets on a single substrate—creates complex thermal landscapes. While this approach extends the life of Moore's Law, it also concentrates heat in unpredictable hotspots, demanding a more sophisticated and effective thermal management solution than ever before. Traditional thermal interface materials (TIMs) and even advanced liquid cooling systems face significant limitations in addressing heat at the microscopic level required by these complex designs.

Forging a Diamond Solution

Diamond has long been recognized as the ultimate thermal conductor, but its practical use in mass-produced electronics has been thwarted by significant hurdles. Historically, integrating diamond has been plagued by issues of surface roughness, which prevents effective bonding with other semiconductor materials, and a lack of scalable manufacturing processes compatible with existing fabrication plants (fabs).

Diamond Quanta claims to have cracked this code with its Adamantine Thermal platform. The company's proprietary process addresses these long-standing challenges by combining several key technologies. It starts with a CMOS-compatible, low-temperature diamond growth technique that allows diamond to be deposited on industry-standard 300 mm wafers. Following this, a laser-based densification process polishes the diamond surface to an atomic-level smoothness, making it ready for bonding. Finally, the platform is designed for both wafer-to-wafer (W2W) and chip-to-wafer (C2W) bonding, ensuring it can be seamlessly inserted into existing advanced packaging workflows.

“Thermal is the most immediate and universal entry point for diamond in electronics,” said Adam Khan, Founder and CEO of Diamond Quanta, in the company's press release. “Once diamond can be bonded reliably and at scale, it stops being a research material and becomes a practical platform.”

A primary application for this technology is in engineered-diamond glass interposers. Glass interposers are already gaining favor in the industry for their superior signal integrity and stability. By integrating a layer of engineered diamond, Diamond Quanta can dramatically enhance their thermal performance, allowing heat to spread uniformly and dissipate efficiently while also improving the interposer's mechanical strength and flatness.

Navigating the Competitive Gauntlet

Diamond Quanta is not alone in recognizing the lucrative opportunity in advanced thermal management. The field is populated by established players and agile startups alike, all racing to cool the future of computing. Element Six, a subsidiary of De Beers and a long-time leader in synthetic diamond materials, offers its own portfolio of diamond heat spreaders and recently launched a copper-diamond composite material aimed at the AI and HPC markets.

Meanwhile, newer companies like CoolSem Technologies are developing their own wafer-level thermal solutions. The competitive landscape underscores the urgency and magnitude of the thermal problem. However, Diamond Quanta's strategic focus appears to be its key differentiator. Rather than just selling a material, the company is offering a complete, integrated platform designed for manufacturability. By ensuring its process is compatible with existing fab infrastructure and panel-scale workflows, the company is lowering the barrier to adoption for semiconductor manufacturers and system OEMs.

This strategy is supported by its move to initiate partner evaluation programs with key industry players. Following its engagements at CES 2026, the company is now working to validate its technology within real-world manufacturing environments. This collaborative approach, combined with its participation in respected industry accelerators like the Plug and Play Semiconductor & Photonic program, suggests a deliberate and well-considered plan to penetrate the market.

Beyond Cooling: A 'Physics of Forever' Vision

While Adamantine Thermal addresses the immediate crisis of heat, it represents just one facet of Diamond Quanta's ambitious long-term vision. The company's mission is to "make diamond as accessible to the world as silicon," a goal encapsulated in its tagline, "The Physics of Forever™." This points to a future where diamond's exceptional properties—thermal, optical, and electronic—are leveraged across a wide spectrum of applications.

The thermal platform complements the company's first commercial product, Adamantine Optics™, a diamond-based glass for ultra-durable displays and lenses. Together, these products form the pillars of a broader roadmap that extends into power electronics, quantum computing components, and other advanced systems. The company's foundational work in defect engineering and doping techniques for synthetic diamond could pave the way for diamond-based semiconductors that are far more efficient and resilient than their silicon counterparts.

With seed funding secured in late 2025 and a revenue-generating status reported by market intelligence firms, Diamond Quanta appears to have the financial stability and investor confidence needed to pursue this long-term vision. By providing a scalable bridge from today's passive cooling materials to tomorrow's active diamond-enabled architectures, the company is not just solving a problem; it is attempting to lay the groundwork for a fundamental shift in materials science. This move could ultimately reshape the building blocks of modern technology, ushering in an era of electronics defined by unprecedented durability and performance.