Beyond the Screen: Biel Crystal’s Young Leader Forges ‘Made in China’ to ‘Chinese Brand’ Shift

As supply chains evolve, Biel Crystal is betting on a new generation of leadership. Simon Yeung’s vision is driving the company’s tech upgrade – and a crucial shift for Chinese manufacturing.

Beyond the Screen: Biel Crystal’s Young Leader Forges ‘Made in China’ to ‘Chinese Brand’ Shift

By Sam Lidman

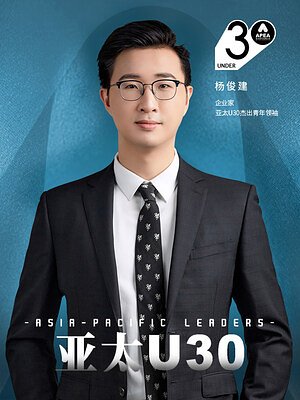

Hong Kong – In a sector often associated with established hierarchies, a new generation is stepping up to reshape China’s manufacturing powerhouse. Simon Yeung, Executive Director and Vice President of Biel Crystal, is a prime example. Recently named to the 2025 Asia-Pacific U30 Outstanding Young Leaders list, Yeung’s leadership is driving a strategic shift for the company – and signaling a broader evolution within the Chinese manufacturing landscape.

Biel Crystal, a global provider of exterior structure and module solutions, is a name largely unknown to consumers. Yet its components are integral to the smartphones, wearables, and increasingly, automotive displays we rely on daily. Serving tech giants like Apple, Samsung, and Tesla, the company quietly operates as a critical link in the global supply chain. But Biel Crystal is no longer content to simply manufacture to specifications. It's aiming to innovate, brand, and climb higher up the value chain.

“The pressure on manufacturers, particularly those serving high-end markets, has shifted,” explains an industry analyst familiar with Biel Crystal’s operations. “It’s no longer enough to be cost-competitive. Clients demand innovation, quality, and a willingness to partner on design and development.”

Yeung’s appointment and subsequent leadership have been instrumental in responding to this shifting landscape. He’s spearheaded a digital transformation initiative, integrating AI and smart manufacturing techniques into Biel Crystal’s operations. This isn’t merely about automating existing processes; it’s about fundamentally rethinking how the company designs, develops, and delivers its products.

“We’re moving away from a ‘cost-plus’ model to a ‘value-driven’ approach,” states a source within Biel Crystal. “This requires a significant investment in R&D, a willingness to take risks, and a leadership team that understands the importance of agility and innovation.”

The centerpiece of this innovation is the company’s proprietary ‘Witch Cloak’ ultra-hard coating technology. Developed in-house, this coating significantly enhances the durability and aesthetic appeal of device exteriors, offering a premium finish that sets Biel Crystal’s components apart. Patents surrounding the technology indicate a significant investment and a strategic commitment to intellectual property.

“The ‘Witch Cloak’ technology isn’t just about making a product look better,” explains a materials science expert. “It’s about adding a functional benefit – increased scratch resistance and longevity – that justifies a higher price point and strengthens Biel Crystal’s value proposition.”

This emphasis on branding and proprietary technology marks a distinct departure from the traditional ‘Made in China’ narrative. While cost-effectiveness remains a factor, Biel Crystal is actively cultivating a ‘Chinese Brand’ identity – one synonymous with quality, innovation, and technological prowess.

“For years, Chinese manufacturers were content to be the world’s workshop,” says an industry observer. “But now, we’re seeing a growing number of companies that are determined to become global leaders in their respective fields. Biel Crystal is a prime example of this ambition.”

Yeung's leadership isn’t happening in a vacuum. A broader trend is underway, with a younger generation of leaders stepping into key roles within Chinese manufacturing. These leaders are often more attuned to the demands of a rapidly evolving technological landscape and more willing to embrace disruptive innovations.

“They’re not afraid to challenge established norms and experiment with new approaches,” says a consultant specializing in Chinese manufacturing. “They understand that innovation is the key to long-term success.”

However, this transition isn’t without its challenges. Integrating new technologies, fostering a culture of innovation, and attracting top talent require significant investment and a long-term vision. Furthermore, Biel Crystal, like many manufacturers, faces the ongoing risks associated with global supply chain disruptions and geopolitical instability.

The company’s reliance on a handful of major clients also presents a potential vulnerability. While these partnerships provide stability and revenue, they also limit Biel Crystal’s flexibility and bargaining power.

Despite these challenges, Biel Crystal appears well-positioned to capitalize on the evolving dynamics of the global manufacturing landscape. Yeung’s leadership, combined with the company’s commitment to innovation and quality, is driving a strategic shift that could reshape the future of Chinese manufacturing.

“Biel Crystal is not just building components; it’s building a brand and forging a new identity for Chinese manufacturing,” concludes the industry analyst. “And that’s a story worth watching.”

Key Takeaways:

- Shift in Focus: Biel Crystal is transitioning from a pure manufacturing model to one focused on innovation, branding, and value creation.

- Proprietary Technology: The ‘Witch Cloak’ coating demonstrates the company’s commitment to R&D and intellectual property.

- Young Leadership: Simon Yeung’s appointment signals a broader trend of younger leaders driving change in Chinese manufacturing.

- Challenges Remain: Supply chain risks, client dependencies, and the need for ongoing investment pose challenges to Biel Crystal’s long-term success.