The Quiet Engine Powering Mach 7 Aerospace Dreams

- 80 meters: Length of each accumulator tube at the DLR facility.

- Mach 7: Maximum airspeed achieved in the wind tunnel tests.

- 15 minutes: Time taken by the COBRA pump to evacuate the vacuum vessel, half the time of its predecessor.

Experts agree that advancements in vacuum technology, such as the COBRA screw vacuum pump, are critical to enhancing the efficiency, accuracy, and sustainability of hypersonic aerospace research.

The Quiet Engine Powering Mach 7 Aerospace Dreams

GÖTTINGEN, Germany – November 24, 2025 – Flanked by two enormous accumulator tubes, each stretching over 80 meters, the German Aerospace Center's (DLR) Institute of Aerodynamics and Flow Technology in Göttingen doesn't immediately reveal its most futuristic secrets. Inside this facility, a cornerstone of aerospace research since its inception, scientists are chasing the future of flight—a future that is faster, safer, and more efficient. They do this by recreating the physics of supersonic and hypersonic travel, pushing air to speeds of up to Mach 7, or seven times the speed of sound.

This high-stakes research, which provides the foundational data for everything from next-generation passenger jets to interplanetary vehicles, hinges on a remarkable piece of engineering developed in the 1950s: the Ludwieg Tube Wind Tunnel (RWG). Yet, the continued relevance of this historic apparatus depends on a modern, and often overlooked, industrial workhorse. A new COBRA screw vacuum pump from Busch Vacuum Solutions, installed in 2021, has not only revitalized the facility but also highlights a critical truth of innovation: breakthrough moments are often powered by unseen, foundational technologies working flawlessly in the background.

The Invisible Engine of Innovation

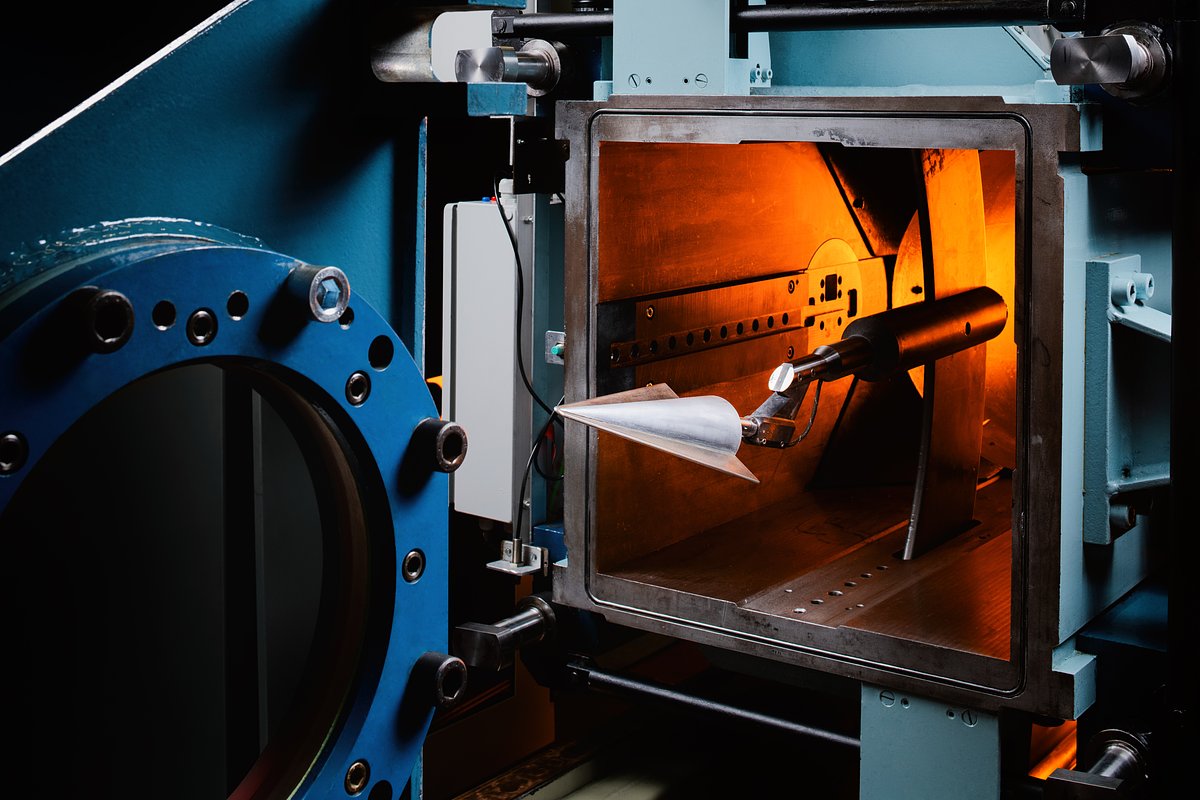

The operating principle of the Ludwieg tube is an elegant interplay of brute force and precise control. Air is first compressed to immense pressures—up to 40 bar—inside the long accumulator tubes. To start a test, a quick-action valve snaps open, releasing this compressed air toward a specially shaped ultrasonic nozzle. The critical element that makes this process efficient and controllable is what lies at the other end: a massive 50 m³ vacuum vessel.

By creating a near-vacuum in this vessel, researchers generate a massive pressure differential that accelerates the air to incredible speeds through the test section, where models of aircraft, sensors, or material samples are placed. This combination of high pressure and deep vacuum is the engine of the wind tunnel. “Thanks to vacuum technology, we can carry out the tests much more efficiently,” explains Dr. Erich Schülein, Group Leader and Scientific Supervisor of the RWG. “Without it, we would not only have to significantly increase the boost pressure in the accumulator tube, but also the requirements for the stability of the entire system... The technical effort required for this would be enormous. The vacuum pump does this work for us.”

For over five decades, an old rotary vane vacuum pump performed this vital function. But in 2021, it was replaced by the modern, dry-running COBRA NX screw vacuum pump. This upgrade wasn't merely a replacement; it was a fundamental enhancement of the facility's core capabilities, enabling DLR to push the boundaries of its research with greater speed and precision.

A Revolution in Research Efficiency

The impact of the new vacuum technology was immediate and transformative. The most striking improvement was in speed. The COBRA pump evacuates the massive vacuum vessel to its target pressure twice as fast as its predecessor, slashing the time required from half an hour to just 15 minutes. In a research environment where every test run is valuable, this doubling of operational tempo significantly increases the potential throughput for experiments, allowing scientists to gather more data in less time.

This efficiency extends directly to sustainability and cost. The shorter run times, combined with an integrated frequency converter that intelligently adapts the pump's speed to the required pressure, yield significant energy savings. In an era where even high-tech research facilities are under pressure to reduce their environmental footprint, such gains are a crucial part of the innovation story. This aligns with a broader industry trend where competitors like Leybold and Edwards also emphasize high-efficiency systems for demanding scientific applications.

The benefits also transformed the daily work environment. Karsten Pfeiffer, Technical Manager of the RWG, notes the dramatic reduction in noise and vibration. “You can't hear anything except a slight buzz,” he says. Previously, the noise from the old pump rendered nearby offices unusable during operation. Now, the research continues without disruption. Furthermore, the move to an oil-free system has eliminated a significant maintenance burden. “In the past, I had to do hands-on work regularly and change the oil—and then also change my resulting dirty clothes,” Pfeiffer recalls. “This is no longer necessary.” This shift to a clean, low-maintenance system allows the technical staff to focus on the science, not on upkeep.

The Criticality of a Clean Vacuum

The transition to an oil-free pump is more than a matter of convenience; it is a scientific imperative. In the sensitive world of fluid mechanics, where experiments are designed to validate complex numerical simulations, data integrity is paramount. The slightest contamination can compromise results. An oil-lubricated pump introduces the risk of microscopic oil particles entering the airflow, potentially altering the aerodynamic properties being measured or contaminating the surfaces of test models.

“For us, it is crucial that the flow generated in the tube wind tunnel must be clean,” Pfeiffer states. “The tests are often carried out several times, and it is important that the conditions are reproducible at all times.” The COBRA pump’s dry-running screw technology ensures a ‘clean vacuum,’ free from the hydrocarbon contaminants that could skew measurements and undermine the very purpose of the research. This is the validation database that will help refine the computational models used to design the next generation of aircraft. In this context, the absence of oil is a key feature that ensures the purity and reliability of DLR's foundational research, a critical differentiator in the high-stakes field of aerospace testing.

From Legacy to the Hypersonic Horizon

The Ludwieg Tube Wind Tunnel in Göttingen is a living piece of aerospace history. Since 1968, it has played a role in pivotal international projects, including testing a model of the X-38 spacecraft for NASA and ESA, a vehicle designed to return ISS astronauts to Earth in an emergency. The facility’s ability to simulate the enormous heat and mechanical loads of atmospheric re-entry was indispensable.

Today, that legacy continues as DLR’s research informs a new wave of supersonic and hypersonic ambitions. The world is on the cusp of a new era of high-speed flight, with projects like NASA's X-59 QueSST aiming to tame the sonic boom for overland travel, and commercial ventures like Boom Supersonic developing a new generation of passenger aircraft. These projects face immense technical hurdles, from thermal management at speeds above Mach 5 to developing novel propulsion systems and materials.

The experimental work conducted at DLR provides the essential, real-world data needed to solve these challenges. As Dr. Schülein notes, despite incredible advances in computer modeling, “many phenomena in turbulent flows still cannot be adequately and accurately predicted.” The wind tunnel creates the validation database that helps improve these numerical methods. The quiet, efficient, and clean vacuum provided by Busch's technology is a fundamental enabler of this work, ensuring the data gathered is of the highest possible quality. It is a powerful reminder that the path to the hypersonic future is paved not only with bold designs and visionary concepts, but also with the precision and reliability of the industrial technologies that make their testing possible.