The Decarbonization Engine: A New Reactor Tech to Clean Up Industry

- Technology Readiness Level (TRL) of 6: Chemical looping combustion has reached TRL 6, indicating successful validation in an industrial environment.

- 2028 Commercialization Target: Babcock & Wilcox plans to build three commercial-scale hydrogen plants using chemical looping technology by 2028.

- Nearly Pure Hydrogen Production: A 250-kilowatt pilot plant at The Ohio State University successfully produced a nearly pure stream of hydrogen with integrated CO2 capture.

Experts view chemical looping as a highly promising technology for decarbonizing industry, offering efficient CO2 capture and versatile applications in hydrogen and chemical production, with recent advancements accelerating its path to commercialization.

The Decarbonization Engine: How New Reactor Tech Aims to Clean Up Industry

JEONBUK-DO, SOUTH KOREA – January 14, 2026 – As the world grapples with the urgent need to decarbonize its energy and industrial sectors, a promising technology is gaining critical momentum. Researchers from Jeonbuk National University in South Korea have published a landmark review detailing key advancements in chemical looping, a process with the potential to slash carbon emissions from power plants and chemical factories with unprecedented efficiency.

The study, published in the high-impact journal Renewable Energy, provides a comprehensive roadmap for optimizing a new generation of industrial reactors. Led by researchers in Professor See Hoon Lee’s Carbon-Negative Green Hydrogen Laboratory, the work synthesizes recent innovations that could accelerate the transition away from polluting fossil fuel techniques. At its core, chemical looping offers an elegant solution to a complex problem: how to capture carbon dioxide (CO2) without the steep energy and cost penalties associated with conventional methods.

Inside the Reactor's Core

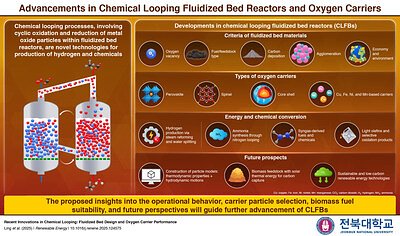

Traditional carbon capture technologies typically bolt on to existing power plants, using chemical "scrubbers" to filter CO2 from exhaust fumes—a process that consumes a significant amount of energy. Chemical looping, however, redesigns the combustion process from the ground up. It uses two interconnected reactors, known as fluidized beds, where fuel and air never mix.

Instead, a solid material called an "oxygen carrier"—typically metal oxide particles—circulates between the two reactors. In one reactor, the oxygen carrier oxidizes the fuel (like natural gas, coal, or even biomass), producing a concentrated stream of CO2 that is inherently captured and ready for storage or utilization. The now-reduced carrier then moves to the second reactor, where it is re-oxidized with air before starting the cycle again. This avoids the energy-intensive step of separating CO2 from other flue gases, a key advantage that could dramatically lower the cost of decarbonization.

The Jeonbuk National University review highlights critical breakthroughs in two main areas: the design of these fluidized bed reactors and the performance of the oxygen carriers themselves. "Our work highlights key advancements in fluidized-bed reactors that enhance reforming, gasification, and hydrogenation within chemical looping systems," noted Dr. Jester Lih Jie Ling, a post-doctoral researcher and an author of the study.

The review emphasizes the development of more robust oxygen carriers—using materials like perovskite, spinel, iron, and copper—that can withstand thousands of cycles without losing their reactivity. "It also emphasizes enhanced oxygen carrier materials with higher reactivity, durability, and resistance—critical attributes for long-term, stable operation," Dr. Ling added. These material science innovations are crucial for making chemical looping a commercially viable, long-term solution for heavy industry.

From Lab to Industrial Scale

While the concept has been developed over decades, recent progress suggests chemical looping is moving out of the laboratory and toward commercial reality. Some forms of the technology, particularly for combustion, have reached a Technology Readiness Level (TRL) of 6, indicating successful validation in a relevant industrial environment.

Across the globe, pilot projects are demonstrating the technology's potential. In the United States, The Ohio State University has successfully operated a 250-kilowatt pilot plant that uses a syngas chemical looping process to produce a nearly pure stream of hydrogen with integrated CO2 capture. Building on this momentum, industrial giant Babcock & Wilcox has announced plans to build three commercial-scale hydrogen plants using chemical looping technology by 2028, citing its feedstock flexibility as a major advantage.

Europe is also a hotbed of development. The EU-backed CLARA initiative has demonstrated biomass-fueled chemical looping, with some researchers projecting commercialization could be just a few years away. In Austria, a demonstration plant is already successfully producing high-purity hydrogen from biogas using a chemical looping process, proving its adaptability to renewable fuel sources. These projects are critical stepping stones, providing the real-world data needed to de-risk the technology for widespread industrial adoption.

A Cleaner Path for Hydrogen and Chemicals

The technology's promise extends far beyond clean power generation. It offers a compelling pathway for producing low-carbon hydrogen, a key element in the future energy mix. Today, most hydrogen is produced via Steam Methane Reforming (SMR), a process that is cost-effective but generates significant CO2 emissions. While adding carbon capture to SMR is possible, chemical looping offers a more integrated and efficient alternative.

Compared to "green hydrogen" produced via electrolysis—which requires massive amounts of renewable electricity to split water—chemical looping can utilize existing fuel infrastructure for natural gas or biomass while still capturing nearly all the CO2. This makes it a vital "blue hydrogen" technology that can bridge the transition to a fully renewable energy system.

Furthermore, the Jeonbuk review points out that advancements in chemical looping enable a wide variety of chemical pathways, allowing for the production of ammonia, syngas-derived fuels, and other valuable chemicals. This versatility positions it as a cornerstone technology for the decarbonization of the broader chemical industry, which is notoriously difficult to abate.

South Korea's Green Tech Ambitions

The research from Jeonbuk National University is not happening in a vacuum. It aligns perfectly with South Korea's national strategy to become a global leader in green technology. In February 2025, the country passed a landmark law to support its carbon capture, utilization, and storage (CCUS) sector, providing the financial and administrative framework needed to build a domestic industry.

Government bodies like the Ministry of Trade, Industry and Energy (MOTIE) are actively exploring large-scale CO2 storage sites and fostering partnerships between academia and industry. This policy support creates a fertile ground for innovations like chemical looping to mature and scale. The work being done at institutions like Jeonbuk National University provides the foundational science that will underpin these national ambitions.

This global push is mirrored by massive funding programs like the EU Innovation Fund and initiatives from the U.S. Department of Energy, which are pouring billions into low-carbon technologies. As Dr. Ling concluded in the press release, the implementation of chemical looping aligns with the "increasing demand for sustainable and low-carbon renewable energy technologies." By providing a detailed guide for improving reactor design and material performance, the new review from Jeonbuk National University serves as an essential guidepost for engineers and policymakers working to build a cleaner industrial future.

📝 This article is still being updated

Are you a relevant expert who could contribute your opinion or insights to this article? We'd love to hear from you. We will give you full credit for your contribution.

Contribute Your Expertise →