Sharpa's North Robot: Solving Dexterity to 'Manufacture Time'

- 22 active degrees of freedom in SharpaWave hands, matching human hand dexterity

- Over 300 windmills assembled autonomously during CES 2026

- 90% of the challenge in robot dexterity lies in the 'last millimeter' of object interaction

Experts would likely conclude that Sharpa's North robot represents a significant advancement in autonomous dexterity, particularly in solving the 'last-millimeter' problem, positioning it as a potential leader in practical, real-world robotic applications.

Sharpa's North Robot: Solving Dexterity to 'Manufacture Time'

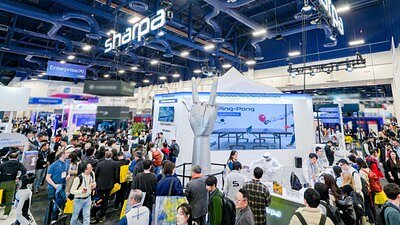

LAS VEGAS, NV – January 19, 2026 – Amid the cacophony of CES 2026, a quiet, focused intensity drew crowds to the Sharpa booth. There, a full-sized humanoid robot named North wasn't performing a scripted dance or a pre-programmed backflip. Instead, for eight hours a day, it was engaged in fully autonomous, unscripted ping-pong rallies with human challengers. The sustained volleys, met with cheers from onlookers, were more than just a spectacle; they were a statement of reliability from a company on a mission to “manufacture time by making robots useful.”

Singapore-based Sharpa, founded in 2024, used the world's biggest tech stage to debut not only its North robot but also the sophisticated AI powering its movements: CraftNet, a hierarchical vision–tactile–language–action (VTLA) model. The demonstrations, which went far beyond ping-pong, signaled a potential turning point in robotics, aiming to solve the persistent bottleneck that has kept autonomous machines from performing meaningful, complex work in the real world: fine manipulation.

Beyond Backflips: Solving the Dexterity Dilemma

For years, the robotics industry has wowed the public with videos of machines exhibiting incredible agility and balance. Yet, translating that dynamism into practical productivity has remained elusive. "Robots can already dance and backflip, but manipulation remains the real bottleneck for useful, autonomous robots," said Alicia Veneziani, Sharpa's Global VP of GTM and President of Europe, in a statement. "At Sharpa, we focus on productivity from day one, which is why we started with the hardest part, the hand."

That focus was on full display. North, powered by the company's Wave dexterous hands, flawlessly executed a quartet of complex, autonomous tasks. Beyond the high-speed reactions required for ping-pong, the robot delicately picked single playing cards from a deck, operated a camera to take over 2,000 instant photos of attendees, and meticulously assembled small windmills.

The windmill task was particularly telling. Requiring more than 30 consecutive successful steps, it represented one of the longest-horizon autonomous manipulation tasks ever demonstrated live. This wasn't a one-off success; North assembled over 300 windmills throughout the event. This sustained, unscripted performance was a strategic choice to build trust and prove that its technology moves beyond brittle, controlled demos into the realm of reliable, repeatable work.

The hardware enabling this feat is the SharpaWave hand, which entered mass production in late 2025. Each hand boasts 22 active degrees of freedom—on par with a human hand—and is equipped with a proprietary dynamic tactile array. This gives the robot a sense of touch with sub-millimeter resolution, a critical component for the 'last-millimeter' problem of physically interacting with objects.

The Brains Behind the Hands: CraftNet's 'Last-Millimeter' Focus

If the Wave hand is the muscle, CraftNet is the nervous system and brain. Sharpa introduced the AI model as the key to unlocking true dexterity. The company argues that while many systems can see and move towards an object, the final moment of contact—the 'last millimeter'—is where most robots fail. Sharpa claims this final interaction phase constitutes “90% of the challenge.”

CraftNet's architecture mimics the human nervous system. It employs a hierarchical, two-system approach to manipulation. A 'Motion Brain' (System 1) handles the broader, coarse movements, like positioning the arm and hand near an object. But the crucial work is done by the 'Interaction Brain' (System 0), which operates at a high frequency to manage the delicate, force-sensitive actions of contact and manipulation. This system provides a 'common sense' of touch, allowing the robot to adjust its grip and pressure in real-time, much like a person unconsciously handles a delicate object.

This focus on touch is a core tenet for the company, which bluntly states, "Tactileless is the new blindness" for robots. By integrating vision, language, and especially high-fidelity tactile feedback, CraftNet aims to give robots the nuanced understanding of the physical world needed to move from clumsy machines to adept co-workers. This integrated hardware and software approach is what the company believes will finally enable scalable autonomous manipulation for real-world deployment.

Navigating a Crowded Field of Humanoids

Sharpa is entering an increasingly competitive humanoid robotics space populated by high-profile players like Tesla with its Optimus robot, the dynamically athletic Atlas from Boston Dynamics, Agility Robotics' logistics-focused Digit, and Sanctuary AI's Phoenix. While each competitor has its own strengths—from dynamic mobility to specific industrial applications—Sharpa is carving out its niche by relentlessly focusing on general-purpose fine manipulation.

The company’s leadership, composed of co-founders Shaoqing Xiang, David Li, and Kai Sun, brings significant credibility from their past roles at LiDAR giant Hesai Group, as well as experience from Apple and top research universities like Stanford. Bolstered by a $100 million Series A funding round led by Qiming Venture Partners, the two-year-old startup has the resources and expertise to back its ambitious vision. Its strategy appears to be not to build the fastest or strongest robot, but the most dexterous, opening up a vast range of applications in service industries like retail, restaurants, and hotels, and eventually, the home.

The Promise and Peril of 'Manufacturing Time'

Sharpa's mission to 'manufacture time' frames automation as a net positive for humanity, a deposit into a 'time bank' where every manual task assumed by a robot frees up a person for more creative, strategic, or fulfilling work. The economic promise is significant; deploying truly useful robots in service and light industrial sectors could address labor shortages, boost productivity, and drive economic growth.

However, this technological leap also brings profound societal questions to the forefront. Widespread adoption of capable humanoid robots will inevitably impact labor markets, potentially displacing workers in roles that rely on manual dexterity. This raises urgent questions about the future of work, the necessity for large-scale reskilling and upskilling programs, and the ethical considerations of privacy and accountability as autonomous agents become integrated into our daily lives.

The debate is no longer theoretical. As companies like Sharpa move from research labs to production timelines—with North slated for a production release in mid-2026—these discussions become immediate and necessary. The impressive performance at CES 2026 was a powerful demonstration of what is now possible, but the true test will come when North and robots like it step out of the convention hall and into the complexities of the real world.