SENS Tackles Top Cause of Generator Failure with Integrated Systems

- 90% reduction in space: The SuperTorque® 8R system offers up to a 90% reduction in physical footprint compared to traditional starting systems.

- System-level integration: SENS's approach consolidates all critical components into a single, pre-engineered unit, eliminating field assembly errors.

- NiZn battery advantage: The system uses advanced Nickel-Zinc batteries, which provide superior performance and higher temperature tolerance over traditional lead-acid batteries.

Experts in mission-critical power systems would likely conclude that SENS's integrated engine-starting systems represent a significant advancement in reliability, addressing a long-standing vulnerability in backup power infrastructure.

SENS Aims to End Generator Failure with Integrated Power Systems

LONGMONT, Colo. – January 14, 2026 – In an era defined by digital dependency and the relentless need for uptime, the last line of defense against a blackout—the standby generator—is often crippled by its simplest component: the starting battery. Stored Energy Systems (SENS), a veteran in mission-critical power, is addressing this persistent vulnerability head-on with a new class of integrated engine-starting systems, set to be showcased at POWERGEN 2026. The company claims its system-level approach can eliminate what industry experts consistently cite as a leading cause of generator failure, promising a new standard of reliability for the world’s most critical infrastructure.

The Achilles' Heel of Backup Power

For data centers, utilities, hospitals, and industrial facilities, the standby generator is the ultimate safety net. Yet, despite decades of engine optimization, the simple act of starting the engine during an outage remains a significant point of failure. The culprit, more often than not, is not the multi-ton engine itself, but the DC power system tasked with cranking it to life. Industry analyses and maintenance reports consistently point to battery-related issues as a primary reason for generators failing to start.

This vulnerability is deeply rooted in how these systems have traditionally been built. The standard approach involves a fragmented, multi-vendor architecture where batteries, chargers, racks, cabling, and disconnect switches are sourced from various suppliers and assembled in the field. This method introduces significant variability, installation complexity, and numerous potential failure points—from a loose cable to an incompatible charger or a faulty battery. In today's fast-paced environment, marked by compressed construction schedules and skilled labor shortages, the risks associated with this field-assembled approach are magnified.

"When generators fail, it's because the starting system didn't perform when it mattered most," stated Olen Scott, Chief Commercial Officer at SENS, in a recent announcement. "The industry has spent decades optimizing engines, but far less time engineering the DC systems responsible for starting and sustaining them. We're changing that with fully integrated systems that have reliability designed in from day one."

A System-Level Revolution

SENS is challenging the status quo with what it calls a "system-level approach." Instead of leaving assembly and integration to the field, the company pre-engineers, assembles, and factory-tests the entire engine-starting apparatus under one roof. The result is a single, cohesive unit delivered with a single part number, designed to perform reliably under the most demanding conditions.

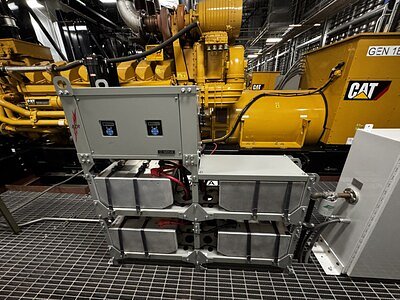

The flagship of this new philosophy is the SuperTorque® 8R. This system consolidates high-performance Nickel-Zinc (NiZn) batteries, an optimized charging system, switching, protection circuits, and disconnects into a single, compact cabinet. By integrating all critical components, SENS eliminates the guesswork and potential for error inherent in multi-vendor systems. The use of advanced NiZn battery technology further enhances reliability, offering superior performance and higher temperature tolerance compared to traditional lead-acid batteries, which are susceptible to degradation and require frequent maintenance.

One of the most striking benefits of this integrated design is its physical footprint. The SuperTorque® 8R boasts up to a 90% reduction in space compared to traditional starting systems. For modern data centers and other dense industrial environments where every square foot is valuable real estate, this space-saving is a significant advantage, allowing for more efficient facility layouts and freeing up room for revenue-generating equipment.

Driving Efficiency Beyond Reliability

While bolstering reliability is the primary goal, the operational and financial benefits of this integrated model extend much further. The traditional process of specifying, procuring, and installing a dozen different components is replaced by ordering a single, pre-certified unit. This dramatically simplifies the supply chain and reduces on-site installation time and labor costs—a critical advantage at a time when construction projects face tight deadlines and a shortage of skilled technicians.

Furthermore, SENS's design aims to decrease or even eliminate the need for routine battery maintenance, a constant operational burden for facility managers. Traditional battery systems require regular inspections, cleaning of terminals, and periodic replacement, all of which consume time and resources. The SuperTorque® 8R, with its long-life NiZn batteries and factory-sealed design, is engineered for a "set it and forget it" lifecycle, translating directly into lower operational expenditures over the life of the generator.

This philosophy of integration is not limited to engine starting. SENS is also showcasing its PowerCab™2, a fully integrated DC power system, or UPS, for applications like utility switchgear and power generation control. By packaging energy storage, power conversion, and distribution into a factory-assembled cabinet, PowerCab™2 applies the same principles of simplicity and reliability to a broader range of mission-critical DC power needs, demonstrating a comprehensive strategy to de-risk critical infrastructure.

Powering a More Resilient Future

The push for more reliable backup power comes at a crucial moment. The global economy's reliance on digital infrastructure is accelerating, with the proliferation of AI, IoT, and cloud computing placing unprecedented demands on data centers. These facilities are now considered a major reliability risk for the power grid itself due to their massive and growing energy consumption. Simultaneously, aging grid infrastructure and the increasing frequency of extreme weather events are testing the limits of energy resilience.

In this context, innovations that enhance the dependability of backup power are not just incremental improvements; they are essential components of a more resilient future. By ensuring that the last line of defense actually works when called upon, integrated systems like those from SENS play a vital role in modernizing infrastructure and safeguarding continuity. This move towards pre-engineered, modular, and highly reliable power components aligns with broader industry trends favoring faster deployment, operational simplicity, and robust performance.

As industry leaders gather at POWERGEN 2026, the conversation will undoubtedly focus on building a smarter, stronger, and more dependable energy landscape. The shift from fragmented, field-built systems to integrated, factory-proven solutions represents a significant step in that direction, promising to turn the weakest link in the backup power chain into a source of unwavering strength.

📝 This article is still being updated

Are you a relevant expert who could contribute your opinion or insights to this article? We'd love to hear from you. We will give you full credit for your contribution.

Contribute Your Expertise →