ScioSense Sensor Unlocks Wireless Fluid Monitoring for IoT & Industry

- Power Efficiency: The UFM-02 operates on an average current of just 50 microamperes (µA), a 40x reduction from its predecessor (2 milliamperes).

- Flow Sensitivity: Capable of detecting flows as low as 0.03 liters per minute, critical for leak detection.

- Market Potential: Smart water management sector projected to exceed $38 billion by the early 2030s.

Experts agree that the UFM-02's ultra-low power consumption and wireless capabilities make it a transformative technology for IoT and industrial fluid monitoring, enabling scalable, efficient, and data-driven resource management across multiple sectors.

ScioSense Unlocks Wireless Fluid Monitoring with New Low-Power Sensor

EINDHOVEN, NETHERLANDS – November 26, 2025 – In a move that could fundamentally reshape how industries and consumers manage critical fluids, sensor manufacturer ScioSense has launched the UFM-02, an ultrasonic flow sensing module with an exceptionally low power requirement. While the release of a new component might seem incremental, the strategic implications of this technology are profound. By enabling multi-year battery life for precise flow measurement, the UFM-02 effectively cuts the cord on a new generation of smart devices, opening the door for widespread, wireless monitoring of everything from municipal water lines and agricultural irrigation to industrial coolants and smart home appliances. This development arrives at a critical juncture, as concerns over resource scarcity and the drive for greater industrial efficiency place a premium on granular, real-time data.

A Breakthrough in Sensing Efficiency

The core innovation of the UFM-02 lies in its remarkable power efficiency. The module operates on an average current of just 50 microamperes (µA), a drastic reduction from its predecessor, the UFM-01, which required 2 milliamperes (mA). This leap in efficiency is what transforms the device from a niche component into a foundational technology for the battery-powered Internet of Things (IoT). It allows a device equipped with the UFM-02 to operate for years on a single standard battery, eliminating the need for costly and complex power cabling.

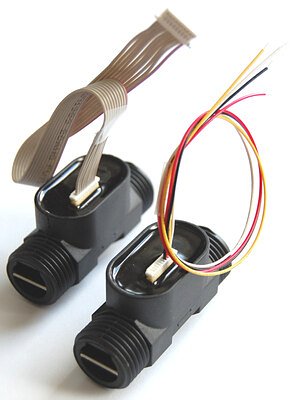

This breakthrough is significant because it removes a primary barrier to deploying sensors in remote or hard-to-reach locations. ScioSense offers the UFM-02 not as a bare integrated circuit, but as a complete, factory-calibrated module. It includes the spool piece (the section of pipe), twin ultrasonic transducers, and the high-precision measurement circuitry based on the company's advanced converter chips. This ready-to-use design dramatically simplifies the integration process for Original Equipment Manufacturers (OEMs), reducing development time and cost for companies looking to add intelligent fluid management to their products.

The technology itself, based on ultrasonic waves, offers inherent advantages over traditional mechanical flow meters. With no turbines or other moving parts, the UFM-02 is not subject to mechanical wear and tear, ensuring a long operational lifetime and consistent reliability. This design also makes it highly sensitive, capable of detecting flows as low as 0.03 liters per minute, a critical feature for effective leak detection. As Andreas Blocherer, Senior Product Manager at ScioSense, stated, 'The introduction of a truly low-power implementation of ultrasonic flow sensing makes this fantastic technology accessible to a new range of applications...flow sensing or leak detection can be implemented anywhere.'

Redefining Smart Water and Resource Management

The most immediate and impactful application of this technology is in smart water management, a sector projected to more than double in value to over $38 billion by the early 2030s. This growth is fueled by the urgent need to address global water scarcity and repair aging infrastructure, which is responsible for trillions of gallons of water lost to leaks annually.

The UFM-02's ability to operate wirelessly for years makes it an ideal solution for retrofitting existing systems and deploying new ones at scale. In a residential setting, it can be integrated into smart faucets, toilets, and water heaters to provide homeowners with detailed insights into their consumption and instant alerts for costly leaks. For municipal water utilities, deploying such sensors across a distribution network can create a real-time map of water flow, enabling a proactive approach to maintenance and dramatically reducing non-revenue water loss.

Beyond urban infrastructure, the implications for agriculture are vast. Smart irrigation systems equipped with low-power, wireless flow sensors can deliver precisely the right amount of water to crops, optimizing growth while conserving a precious resource. This capability moves agriculture away from timed watering schedules toward data-driven resource allocation, boosting crop yields and sustainability in an industry under increasing pressure from climate change. The sensor's food-grade rating and multiple interface options—from a simple pulse output to a detailed SPI digital data stream providing volume, flow rate, and temperature—give designers the flexibility to build everything from a simple leak alert to a sophisticated resource management platform.

Fueling Industrial Efficiency and Predictive Maintenance

While water conservation presents a compelling case, the UFM-02's potential extends deep into the industrial sector, where it serves as a key enabler for the next wave of the Industrial IoT (IIoT). In manufacturing, chemical processing, and energy production, the precise monitoring of fluids—be it coolants, lubricants, or chemical inputs—is critical for safety, quality, and efficiency.

Traditionally, monitoring these systems has been complex and expensive. The UFM-02 changes this by offering a cost-effective way to gather granular data. One of the most powerful applications is in predictive maintenance. For instance, instead of replacing industrial filters on a fixed schedule, which often leads to premature disposal or costly system failures, companies can now monitor the total volume of fluid that has passed through them. The sensor's digital output can trigger a maintenance alert precisely when a filter reaches the end of its effective life, optimizing resource use, minimizing downtime, and reducing material waste.

This shift from reactive or scheduled maintenance to a predictive, data-driven model is at the heart of the Industry 4.0 transformation. By providing accurate, real-time flow data, these sensors feed the analytics engines that drive operational intelligence. This allows plant managers to identify inefficiencies, prevent catastrophic failures, and continuously optimize processes for lower cost and a smaller environmental footprint. The ability to deploy these sensors without the constraint of power infrastructure means that even the most remote or challenging parts of an industrial facility can be brought online and integrated into a digital twin or centralized control system. This widespread data collection is foundational for building more resilient, competitive, and sustainable industrial operations.

The launch of the UFM-02 is more than just a product announcement; it represents the maturation of a key enabling technology. By solving the critical challenge of power consumption, ScioSense has made precise, reliable fluid monitoring accessible for mass deployment. This small component is poised to have an outsized impact, quietly powering a future where resources are managed more intelligently, infrastructure is more resilient, and industries operate with unprecedented efficiency. It is a clear example of how advancements at the component level can unlock strategic capabilities across entire sectors of the economy.