Roboteon’s Certified Platform Aims to Heal Ailing Supply Chains

- Roboteon's Robotics Fulfillment and Orchestration Platform is now certified on Microsoft's Commercial Marketplace, offering seamless integration with Dynamics 365 ERP.

- The platform enables intelligent orchestration of diverse robotic fleets, reducing custom integration costs and time.

- Designed to enhance healthcare supply chains, ensuring faster, more accurate delivery of critical medical supplies.

Experts agree that Roboteon’s certified platform addresses critical integration challenges in warehouse automation, enabling more resilient and efficient supply chains, particularly in high-stakes healthcare logistics.

Roboteon’s Certified Platform Aims to Heal Ailing Supply Chains

SAN JOSE, CA – December 03, 2025

The digital nervous system of modern logistics just received a significant upgrade. Roboteon Inc., an innovator in intelligent robotics software, has announced that its Robotics Fulfillment and Orchestration Platform has achieved Microsoft Commercial Marketplace certification. Now available on Microsoft AppSource, the solution offers a pre-built, validated bridge between advanced warehouse robotics and Microsoft’s widely used Dynamics 365 enterprise resource planning (ERP) system. While this news resonates across the manufacturing and retail sectors, its most profound implications may lie within the intricate, high-stakes world of the healthcare supply chain.

For years, the promise of a fully automated, hyper-efficient warehouse has been just out of reach for many organizations, tangled in a web of proprietary systems and complex integration challenges. Roboteon's certification represents a crucial step in democratizing and streamlining this transformation, offering a plug-and-play-style approach where custom-coded chaos once reigned. This development isn't merely about moving boxes faster; it's about building the resilient infrastructure necessary to deliver life-saving medicines, medical devices, and critical supplies with unprecedented speed and accuracy.

The Integration Bottleneck in Modern Warehousing

The pressure on global supply chains has never been greater. A persistent labor shortage, coupled with rising fulfillment costs and increasing consumer expectations, has created a perfect storm for logistics operators. Automation, particularly through autonomous mobile robots (AMRs), has emerged as the clear solution. Yet, the path to automation has been fraught with obstacles.

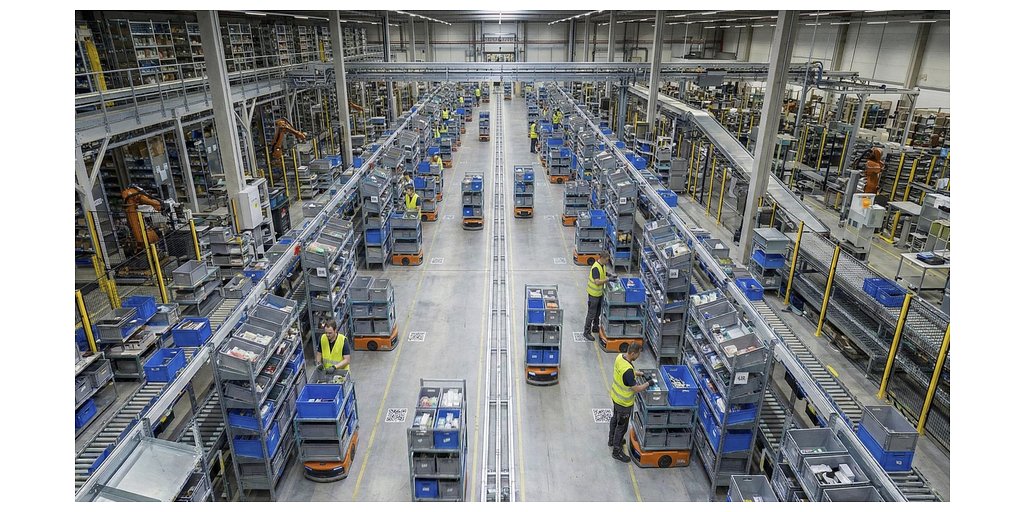

Most warehouses are not pristine, “greenfield” sites. They are complex, “brownfield” environments with a mix of existing infrastructure, legacy software, and a human workforce. Introducing robotics into this mix often creates more problems than it solves. Companies frequently find themselves wrestling with a heterogeneous fleet of robots from different vendors, each with its own proprietary software and communication protocols. Getting a robot from Vendor A to work seamlessly with a conveyor system from Vendor B and a Warehouse Management System (WMS) like Dynamics 365 has historically required massive investments in custom integration projects. These projects are not only expensive and time-consuming but also brittle and difficult to scale.

The result is often a state of digital paralysis, where companies are unable to unlock the full potential of their automation investments. Worse, they face the dreaded “vendor lock-in,” tethered to a single robotics provider’s ecosystem, which stifles innovation and limits future flexibility. This integration bottleneck has been a primary barrier to building the agile, responsive supply chains needed to navigate modern disruptions.

A Certified Bridge for Dynamics 365

Roboteon’s Microsoft certification directly addresses this critical pain point. By achieving a validated status on the Microsoft Commercial Marketplace, the platform offers a seal of approval, assuring Dynamics 365 users that the solution meets Microsoft’s standards for security, performance, and integration readiness. It effectively de-risks the adoption of advanced robotics.

The core of the solution is an intelligent middleware platform with a pre-built connector for Microsoft Dynamics 365 Warehouse Management APIs. Instead of building custom connections from scratch, businesses can now deploy a standardized bridge that translates instructions from the D365 WMS into actionable missions for a diverse fleet of robots. It orchestrates the flow of information in real-time, providing mission status updates and exception handling back to the central system.

“The Roboteon platform empowers Microsoft Dynamics 365 users to achieve success with current and future robotics initiatives in both distribution and manufacturing,” said Raj Senguttuvan, SVP of Product at Roboteon, in the company’s announcement. This statement underscores the platform’s role as an enabler, moving the focus from the challenge of integration to the opportunity of optimization. Built on a flexible microservices-based architecture, the platform is designed for agility, allowing for rapid deployments and faster time-to-value.

Orchestration, Not Just Automation

The true innovation behind platforms like Roboteon’s lies in the shift from simple automation to intelligent orchestration. It’s a concept that industry analysts at firms like Gartner have termed a Multi-Agent Orchestration Platform (MAOP). The goal is not just to command a single robot but to conduct an entire symphony of human and robotic resources for maximum efficiency.

This is where the platform’s vendor-agnostic design becomes a strategic advantage. It acts as a universal translator and conductor, allowing a warehouse to deploy the best robot for each specific task—whether it’s a small AMR for piece picking, a larger one for pallet movement, or a robotic arm for sorting—regardless of the manufacturer. This Universal Fleet Manager provides a single pane of glass for monitoring and controlling the entire automated ecosystem, breaking down the silos that have traditionally hampered performance.

Driving this orchestration is a powerful AI and machine learning engine. The system doesn't just dispatch tasks on a first-come, first-served basis. It analyzes real-time floor conditions, inventory levels, and order priorities to dynamically assign tasks to the best-suited resource, whether human or robot. Advanced simulation capabilities allow operators to model different scenarios, identify potential bottlenecks before they occur, and perform ROI analysis on future automation investments. It even features a “Warehouse GPT” to provide interactive training and productivity insights to operators on the floor, further blending human expertise with AI-driven efficiency.

Curing the Ailing Healthcare Supply Chain

Nowhere is the need for such precision, efficiency, and resilience more acute than in healthcare. The distribution of pharmaceuticals, medical devices, and hospital supplies is a zero-error game. A delay in a shipment of surgical instruments or a temperature-sensitive biologic can have immediate and severe consequences for patient care. The healthcare supply chain is also burdened by immense regulatory pressure, requiring meticulous tracking and tracing from manufacturer to patient.

Roboteon's certified integration with Dynamics 365 offers a powerful prescription for these challenges. For a pharmaceutical distributor, the platform can orchestrate a fleet of robots to pick, pack, and ship orders with near-perfect accuracy, minimizing the risk of dispensing errors. Its ability to manage both human and robotic workflows is critical in environments that require specialized handling or pharmacist verification. The AI-driven optimization can prioritize urgent orders for emergency rooms or operating theaters, ensuring critical supplies arrive precisely when needed.

In medical device manufacturing and distribution, where components are often high-value and serialized, the platform ensures end-to-end traceability. By seamlessly connecting the ERP’s inventory data with the physical movement of goods on the warehouse floor, it creates a robust digital twin of the entire operation. This not only enhances efficiency but also simplifies compliance with regulations like the FDA's Unique Device Identification (UDI) system.

Ultimately, this technology helps build a more shock-proof healthcare supply chain. The flexibility to quickly scale operations or reconfigure workflows using a mix of robotic vendors allows health systems and their suppliers to better respond to sudden demand surges, as seen during public health crises. By removing the friction in warehouse logistics, these platforms ensure that the focus remains where it should be: on delivering the right treatment to the right patient at the right time.