Graphite's New Frontier: From EV Batteries to Stealth Technology

- Global EMI Shielding Market: Valued at over $7.3 billion in 2024, projected to reach $10 billion by 2030.

- Shielding Effectiveness: NMG’s composites achieve 60–70 dB at frequencies below 2 GHz, blocking 99.9999% of electromagnetic energy.

- Strategic Market Expansion: NMG’s graphite-polymer composites now target defense, aerospace, and advanced telecommunications.

Experts view NMG’s breakthrough in graphite-polymer composites as a strategic pivot into high-growth, high-margin markets, leveraging its sustainable supply chain and technical performance to compete in defense and advanced telecommunications.

Graphite's New Frontier: From EV Batteries to Stealth Technology

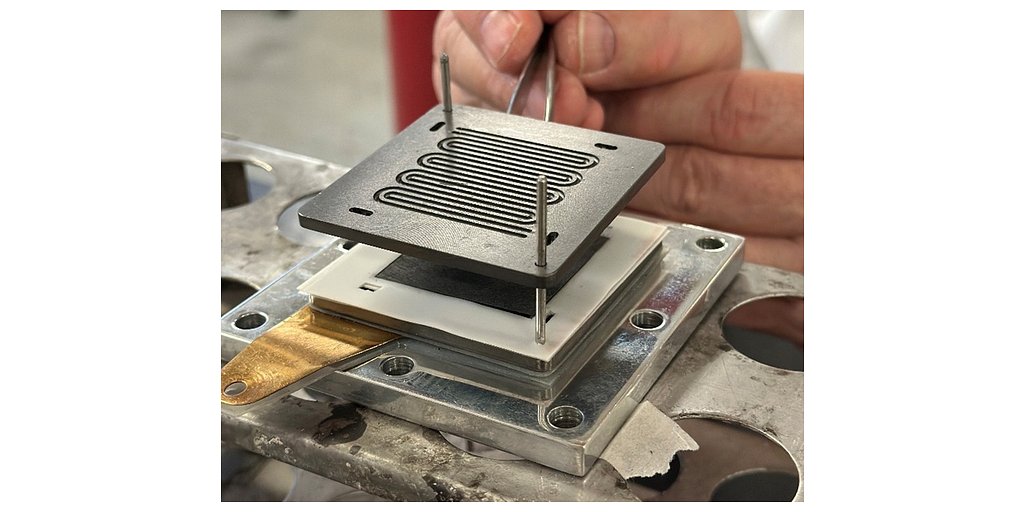

MONTRÉAL, QC – November 25, 2025 – A material once primarily destined for the electric vehicle revolution is now being primed for the front lines of digital and physical defense. Nouveau Monde Graphite Inc. (NMG), a company building an integrated carbon-neutral graphite supply chain in Québec, has announced a pivotal breakthrough: its graphite-polymer composites, initially developed for fuel-cell bipolar plates, demonstrate exceptional capabilities for electromagnetic interference (EMI) shielding. This strategic diversification catapults the company from the crowded battery materials space into the high-stakes, high-margin worlds of defense, aerospace, and advanced telecommunications.

The discovery, stemming from collaborative research with Canadian universities, reveals the multi-functional potential of NMG’s natural graphite. What was designed to manage energy flow in a fuel cell can now block disruptive electronic signals and potentially even absorb radar waves, opening a pathway to stealth applications.

“These results highlight the adaptability of our graphite materials and the depth of our scientific partnerships,” stated Eric Desaulniers, Founder, President, and CEO of NMG, in a recent announcement. “We are transforming graphite innovation into multifunctional solutions that we believe will help us optimize our future sales mix and margins as we contemplate entering new value-added markets.”

The Exploding Market for Digital Invisibility

NMG's pivot is not just a scientific curiosity; it's a shrewd strategic move into a rapidly expanding market. The global demand for EMI shielding, valued at over $7.3 billion in 2024, is projected to climb towards $10 billion by the end of the decade. This growth is fueled by the relentless digitalization of our world.

The rollout of 5G and the forthcoming 6G networks requires dense clusters of high-frequency equipment that can easily interfere with one another, demanding robust shielding. In the automotive sector, the transition to electric and autonomous vehicles is turning cars into sophisticated data centers on wheels. Each EV can contain over 70 electronic control units (ECUs), all of which must operate flawlessly without electromagnetic crosstalk. The automotive segment for EMI shielding is consequently expected to see the fastest growth, ensuring vehicle safety and reliability.

Nowhere is the need more critical than in defense and aerospace. Modern military operations depend on a seamless web of communication, sensor, and navigation systems. Protecting these mission-critical electronics from enemy jamming, electromagnetic pulses (EMP), and electronic warfare is a paramount national security concern. High-performance shielding is the invisible armor that makes this digital resilience possible.

A Material of Strategic Duality

The technical performance of NMG’s composites places them squarely in the sweet spot for these demanding applications. Independent testing compliant with the ASTM D4935 standard confirmed the materials achieved 60–70 decibels (dB) of shielding effectiveness at frequencies below 2 GHz. To put this in perspective, a 60 dB reduction means that only 0.0001% of the electromagnetic energy passes through the material, a level that meets or surpasses many commercial telecom and automotive requirements.

However, NMG has its sights set higher. The company is actively working to push performance toward the 80 dB benchmark and beyond, a level required for many stringent defense-grade applications governed by standards like the U.S. Department of Defense’s MIL-STD-461. Achieving this would position NMG’s composites as a viable, lightweight alternative to traditional metallic shielding.

Graphite composites offer a strategic bridge between polymers, which are light but generally poor at shielding, and metals, which are effective but heavy. NMG’s solution promises the best of both worlds: robust shielding combined with the design flexibility and weight savings of a composite. Furthermore, the company is exploring the integration of radar absorption and thermal/infrared control functionalities. This creates the potential for a single, multi-functional material that can provide electronic shielding, thermal management, and stealth characteristics—a holy grail for designers of next-generation aircraft, drones, and satellites.

Navigating a Crowded and Competitive Field

The EMI shielding market is not without its incumbents. Giants like Parker Hannifin’s Chomerics division, 3M, and DuPont’s Laird Performance Materials have long dominated the space with a vast portfolio of conductive elastomers, coatings, and metal gaskets. However, NMG is not aiming for a head-on collision. Instead, it is carving out a niche based on a unique value proposition.

First is the multi-functional nature of the material itself. A composite that can serve structural, energy, and shielding purposes simultaneously reduces complexity and weight. Second is the sustainability angle. NMG is committed to developing the world's first all-electric open-pit mine and running its processing facilities on clean hydropower, offering a carbon-neutral material to industries increasingly under ESG scrutiny. For defense and government contractors, a secure, ethically sourced material is a powerful differentiator.

This leads to NMG’s most significant competitive advantage: its geography. The company is building a fully integrated, mine-to-market supply chain entirely within North America. In an era defined by geopolitical friction and fragile global logistics, this offers Western industries a secure and resilient source for a critical advanced material, reducing dependence on foreign suppliers.

Forging a Resilient Western Supply Chain

The strategic importance of NMG’s business plan cannot be overstated. The company’s two-phase development of the Matawinie Mine for graphite concentrate and the Bécancour Battery Material Plant for advanced processing is foundational to its ambitions. With backing from major customers like Panasonic Energy and General Motors through offtake agreements, the viability of its core battery material business is already well-validated.

This new venture into EMI shielding and defense applications leverages that same foundation. The large-flake graphite required for these advanced composites will be sourced from the Matawinie Mine, creating a high-value outlet for material that might be less suitable for battery anodes. This diversifies NMG's product portfolio and revenue streams, de-risking its business model from the fluctuations of a single market.

By establishing this capability in Québec, NMG is directly addressing a strategic vulnerability for the U.S., Canada, and their allies. The ability to produce advanced, defense-grade materials at home is a critical component of national and economic security. This move transforms NMG from a simple resource company into a key enabler of technological sovereignty, positioning it at the intersection of clean energy, digital infrastructure, and national defense.