Framing Success: How Data-Driven Strategy Builds a Window & Door Empire

- 3 consecutive years on the SMU Cox Dallas 100™ list, ranking 4th (2022), 33rd (2023), and 55th (2025).

- AI-driven demand forecasting reduces excess inventory and optimizes production.

- Computer vision systems improve quality control by detecting microscopic defects.

Experts would conclude that Elevate Windows & Doors' sustained growth is a testament to the transformative power of AI and data-driven strategies in traditional manufacturing sectors, proving that operational efficiency and innovation are key to competitive advantage.

Framing Success: How Data-Driven Strategy Builds a Window & Door Empire

GRAND PRAIRIE, TX – November 24, 2025 – When a company in a sector as traditional as residential window and door manufacturing earns a spot on a prestigious growth list, it’s a notable achievement. When it happens for a third consecutive year, it signals something deeper than a momentary boom. Elevate Windows & Doors, a Grand Prairie-based manufacturer, recently announced its third inclusion on the SMU Cox Dallas 100™ list, an award honoring the fastest-growing private enterprises in North Texas. While the press release credits product innovation and a customer-centered model, the story behind such sustained velocity in a legacy industry points to a more modern blueprint: the strategic application of data and intelligent automation.

This isn't just a story about a successful local company; it's a real-world example of how the principles of AI and data analytics are becoming the silent engines of growth, even in sectors not typically associated with high-tech disruption. The tangible impact on operational efficiency and strategic innovation is rewriting the rules for success.

Decoding Sustained Growth in a Traditional Sector

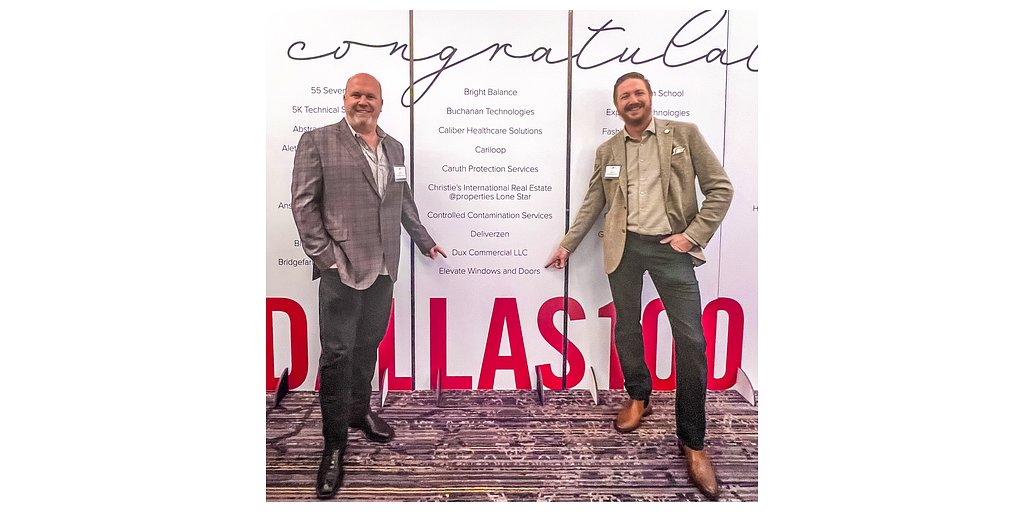

The SMU Cox Dallas 100™ is no mere vanity award. For 35 years, the Caruth Institute for Entrepreneurship has employed a rigorous methodology, verifying sales growth over a three-year period through audited financial statements. Making the list once is difficult; a three-year streak is exceptional. Elevate’s journey—ranking an incredible fourth in 2022, thirty-third in 2023, and a strong fifty-fifth this year—demonstrates not a fleeting surge, but a durable, scalable business model. Co-Owner Jim Robinson noted the consistency, stating, “it shows the consistency and effort our team brings year after year.”

But what does that “effort” truly entail in the 2020s? In manufacturing, the variables are more complex than ever. Volatile supply chains, skilled labor shortages, and rising customer expectations for customization and speed create a high-stakes environment. The company’s stated focus on “operational efficiency” is the key. A decade ago, this meant lean manufacturing and just-in-time inventory. Today, best-in-class operational efficiency is achieved by harnessing data. It involves creating a digital thread that connects sales forecasts, raw material procurement, production schedules, and final-mile logistics. This is the foundational work required for AI to deliver transformative results. The consistent growth Elevate has demonstrated is a powerful indicator that they have mastered this complex data orchestration, moving beyond intuition-based management to a system of data-driven precision.

The Digital Blueprint for Operational Excellence

For a company that promises “a well-designed product, delivered on time,” the logistical challenge is immense. The modern window and door industry is a ballet of complex variables: countless SKUs, custom dimensions, diverse materials, and fluctuating lead times for components like glass and vinyl extrusions. Excelling here requires more than a good ERP system; it requires predictive capabilities.

This is where AI’s impact becomes clear. Advanced analytics and machine learning algorithms are now essential tools for navigating this complexity. AI-powered demand forecasting can analyze historical sales data, market trends, and even macroeconomic indicators to predict which products will be needed and when, optimizing raw material purchasing and minimizing costly excess inventory. In the factory, AI-driven scheduling systems can optimize production runs to reduce changeover times and maximize machine uptime. Computer vision systems can be deployed for quality control, spotting microscopic defects in materials or assembly that are invisible to the human eye, ensuring higher product quality and reducing waste.

Furthermore, ensuring “timely delivery” in the face of global supply chain disruptions requires a resilient and intelligent logistics network. AI platforms can model entire supply chains to identify potential bottlenecks, suggest alternative shipping routes in real-time, and provide accurate delivery estimates to customers. While Elevate hasn’t put an “AI” sticker on its factory doors, its repeated success in a turbulent market strongly suggests the adoption of these intelligent operational principles. The outcome—consistent, award-winning growth—is the proof.

Innovation Beyond the Glass Pane

Elevate’s success isn’t just built on efficiency; it’s also driven by “product innovation.” The company specializes in contemporary, energy-efficient products, positioning itself at the forefront of market demand. This focus aligns perfectly with major industry trends where technology is playing an ever-larger role. Designing a truly energy-efficient window is a complex physics problem, involving calculations of thermal transfer, solar heat gain, and air leakage. AI-powered simulation software allows engineers to model and test thousands of design variations virtually, rapidly iterating to find the optimal balance of materials and construction for maximum performance.

Moreover, the trend toward smart home integration is opening new frontiers. While not yet mainstream, windows and doors are becoming connected devices with integrated sensors, automated shading, and smart locks. Staying ahead of this curve requires a forward-oriented approach to R&D. Companies that lead in this space are using AI tools like Natural Language Processing (NLP) to analyze customer reviews, social media chatter, and industry reports to identify emerging desires and pain points, guiding their innovation pipeline.

Elevate's commitment to delivering a “well-designed product” in the contemporary market implies a deep attunement to these evolving aesthetic and functional demands. This attunement is no longer just an art; it is a science, increasingly informed by the vast amounts of data available on consumer preferences and building trends.

Leadership in the Age of Intelligent Manufacturing

The vision to integrate these advanced strategies comes from the top. Co-owners James Gresham and Jim Robinson both possess extensive leadership experience from their time at another major Texas window manufacturer before founding Elevate. This deep industry knowledge, combined with an entrepreneurial drive, creates a powerful combination. They understand the fundamentals of their craft but also appear to recognize the technological shifts required to excel in the modern era. As Co-Owner James Gresham stated, “This recognition reflects the hard work of our team and the trust of our customers and partners.”

That trust is built on delivering results. In today’s market, delivering results consistently is a function of a well-oiled, intelligent operational machine. The leadership challenge is no longer just managing people and processes, but also governing the data and systems that optimize them. Elevate Windows & Doors serves as a powerful case study for the entire manufacturing sector. Their hat-trick on the Dallas 100™ list is more than a local business story; it’s a clear signal that the future of even the most traditional industries is being built on a foundation of data, intelligence, and a relentless drive for efficiency that technology now makes possible. Their success demonstrates that the quiet integration of AI-driven principles is a potent strategy for achieving sustained growth and competitive advantage.