E3 Lithium Fuels EV Future, Ships Battery-Grade Product from Alberta

- 0.5-kilogram lots of battery-grade lithium carbonate shipped to global partners

- 90-95% lithium recovery rate with 99% impurity removal using DLE technology

- $3.7 billion USD after-tax net present value for the Clearwater Project

Experts view E3 Lithium's advancements in Direct Lithium Extraction (DLE) technology as a critical step toward sustainable, scalable lithium production, positioning Canada as a key player in the global EV supply chain.

E3 Lithium Fuels EV Future, Ships Battery-Grade Product from Alberta

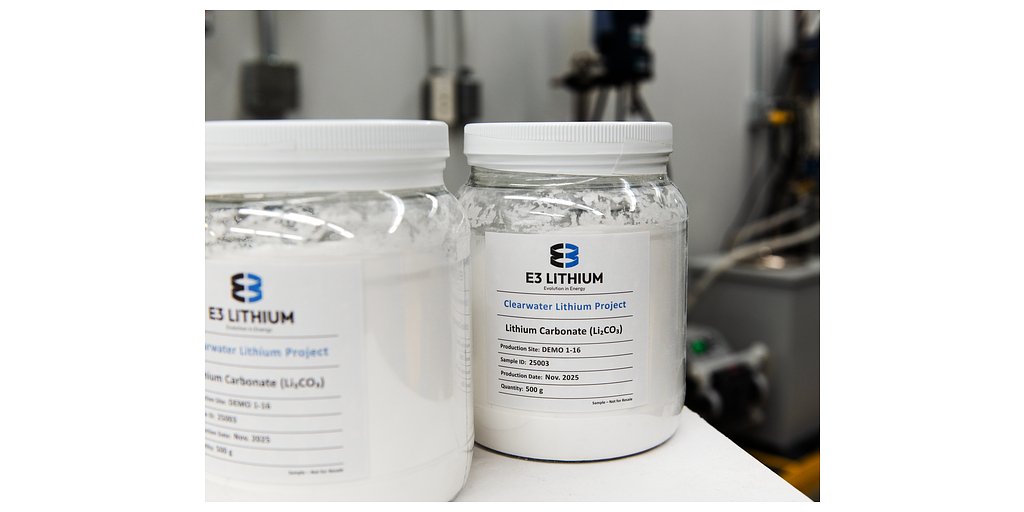

CALGARY, Alberta – January 15, 2026 – In a pivotal move for North America's burgeoning electric vehicle supply chain, Calgary-based E3 Lithium has commenced delivery of battery-grade lithium carbonate to global partners and potential customers. The samples, produced at its demonstration facility near Olds, Alberta, represent a critical validation of the company's technology and a tangible step toward commercial production from one of Canada’s largest lithium resources.

The company is shipping 0.5-kilogram lots, with several prospective buyers requesting multiple kilograms for extensive analysis. This milestone initiates a structured qualification process, essential for securing the long-term offtake agreements needed to finance its large-scale Clearwater Project.

“This milestone marks an important step in E3’s commercial process toward securing long-term offtake agreements and advancing our relationships with key players in the battery and critical minerals industry,” said Chris Doornbos, President and CEO of E3 Lithium. “Our ability to continually produce significant quantities of lithium carbonate from our demonstration facility highlights the size and sophistication of our operations.”

The DLE Difference: A Sustainable Edge

At the heart of E3 Lithium’s operation is its proprietary Direct Lithium Extraction (DLE) technology. This innovative process is designed to selectively pull lithium from the brine held deep within the historic Leduc Formation, a geological reservoir better known for its oil and gas production. By using a specialized adsorbent, the company has demonstrated lithium recovery rates of 90-95% while removing over 99% of impurities.

The shift toward DLE marks a significant technological pivot in the global race for battery materials. Unlike traditional methods such as hard-rock mining or massive evaporation ponds, DLE offers a suite of environmental and efficiency advantages. The process is dramatically faster, extracting lithium in hours or days rather than the months or years required for solar evaporation. This speed is crucial for an industry scrambling to meet demand, which the International Energy Agency (IEA) projects could grow six-fold by 2030.

Environmentally, the benefits are substantial. DLE technology uses significantly less land and up to 90% less water than conventional evaporation ponds, a critical factor in an era of increasing water scarcity. E3 Lithium’s Clearwater Project is being designed as a closed-loop system with a “zero liquid discharge” philosophy, recycling its process water and reinjecting the lithium-depleted brine back underground. This approach eliminates the need for large tailings ponds and minimizes surface disruption.

While E3 Lithium has validated its proprietary system, the company has also tested four third-party DLE technologies, all of which successfully extracted lithium from its brine. This broad-based success signals the growing maturity of DLE and de-risks the technological pathway for the Clearwater Project. E3 is not alone in this pursuit; companies like Standard Lithium in Arkansas and Lilac Solutions in Utah are also advancing DLE projects, underscoring a continent-wide trend toward more sustainable extraction. By 2030, DLE is projected to supply approximately 17% of the world's lithium, carving out a vital role in the future of clean energy.

Building Alberta's Lithium Ecosystem

E3 Lithium’s progress is a cornerstone of Alberta's strategy to diversify its energy-based economy and become a hub for critical minerals. The province’s extensive oil and gas infrastructure, skilled workforce, and well-understood geology provide a unique advantage. The Alberta Energy Regulator (AER) has already established a new regulatory framework for brine-hosted minerals, and E3 Lithium was the first to receive facility permits under these new rules for its demonstration plant—a crucial step that validates the regulatory pathway for future projects.

The company's flagship Clearwater Project is located just north of Calgary and is envisioned as a staged development, starting with a capacity of 12,000 tonnes of lithium carbonate per year and possessing the potential to expand to 36,000 tonnes annually. The project's Pre-Feasibility Study (PFS) outlines a robust economic case, with an after-tax net present value of $3.7 billion USD.

Competition is emerging within the province, with companies like LithiumBank Resources and Grounded Lithium also developing brine-based projects. This growing cluster of activity is creating a dynamic ecosystem, attracting investment and fostering innovation. The federal and provincial governments are actively supporting this shift. E3 Lithium has secured C$27 million from the federal Strategic Innovation Fund (SIF) and C$4.4 million from the Critical Minerals Infrastructure Fund (CMIF) to support pre-construction engineering and design. This government backing, combined with Canada's 30% Investment Tax Credit for clean technology, significantly strengthens the project's financial footing.

The Path to Commercial Production

With product samples now in the hands of potential buyers, E3 Lithium is focused on the final hurdles to commercialization. The estimated upfront capital expenditure for the first stage of the Clearwater Project is a substantial $2.47 billion USD. The company's financing strategy is centered on securing project-level investment from strategic partners in the automotive, battery, or energy sectors, rather than diluting its equity at the corporate level.

The data gathered from the currently operating demonstration facility is critical for completing the Front End Engineering and Design (FEED) study, which will pave the way for a full Feasibility Study expected in 2026. This detailed study is the final technical document required to secure project financing, which the company aims to commence in late 2025.

Looking further down the supply chain, E3 has also partnered with Pure Lithium to explore the development of a lithium metal battery pilot plant in Alberta. This collaboration could see E3's lithium integrated directly into advanced battery components, bypassing intermediate salt steps and capturing more value within the province.

On the regulatory front, the company has submitted its primary Environmental Protection and Enhancement Act (EPEA) application to the AER for its central processing facility. It is also repurposing a former industrial gravel pit for the facility, minimizing new land disturbance and taking on reclamation responsibilities. With construction projected to begin in 2026, E3 Lithium is targeting the start of commercial operations in the second half of 2027, positioning it to become a foundational supplier for North America's domestic battery manufacturing ambitions.

📝 This article is still being updated

Are you a relevant expert who could contribute your opinion or insights to this article? We'd love to hear from you. We will give you full credit for your contribution.

Contribute Your Expertise →