Americium Fuel Breakthrough Powers Next-Gen Space Missions

- Americium-241 has a half-life of 432 years, nearly five times longer than Plutonium-238’s 87.7 years.

- The breakthrough was achieved in just one year, accelerating the timeline for deep space missions.

- The largest reported ceramic americium pellet was produced, enabling industrial-scale manufacturing.

Experts conclude that this americium fuel breakthrough represents a strategic shift in space technology, offering a sustainable and scalable alternative to plutonium for deep space missions, while positioning the UK as a key player in powering future off-world exploration.

Americium Fuel Breakthrough Powers Next-Gen Space Missions

LEICESTER, England & BURLINGTON, Mass. – December 01, 2025 – In a development poised to redefine the limits of space exploration, a transatlantic partnership has solved a critical challenge in nuclear power, creating a scalable production method for a new generation of fuel sources. UK-based Perpetual Atomics and US-based QSA Global, Inc. have successfully manufactured large, stable ceramic pellets from americium, a material that promises to power missions through the decades-long darkness of deep space and the extreme cold of lunar nights.

The breakthrough provides an industrially viable path to manufacturing radioisotope power systems (RPS), the long-lived nuclear batteries essential for missions where solar panels are not an option. This achievement, accomplished in just one year, not only accelerates the timeline for ambitious new voyages but also signals a strategic shift in the global landscape of space technology, positioning the UK as a key player in powering humanity’s future off-world.

The Unseen Infrastructure of Deep Space

For any robotic explorer, from a lunar rover to a deep-space probe, power is the ultimate currency. Beyond the orbit of Mars, the sun’s rays become too faint to reliably power spacecraft, rendering solar panels increasingly ineffective. Historically, the solution has been Plutonium-238 (Pu-238), a radioisotope whose natural decay generates a steady flow of heat. This heat is converted into electricity by Radioisotope Thermoelectric Generators (RTGs) or used directly by Radioisotope Heater Units (RHUs) to keep vital electronics from freezing.

Iconic missions like Voyager, Cassini, and the Mars rover Perseverance owe their success to this technology. However, the global supply of Pu-238 is extremely limited and costly to produce, creating a significant bottleneck for the world’s space agencies. This scarcity has driven a decades-long search for a viable alternative—a fuel source that is not only effective but also available and sustainable. The growing demand for robust energy systems, fueled by plans for lunar habitats and probes to the outer planets, has made this search more urgent than ever.

Americium: A Sustainable Successor from Nuclear Waste

The most promising candidate to emerge is Americium-241 (Am-241). With a half-life of 432 years—nearly five times longer than Pu-238’s 87.7 years—it offers unparalleled longevity for missions that could span generations. Perhaps its most compelling advantage is its origin: Am-241 is a byproduct of the decay of plutonium found in spent fuel from civil nuclear reactors. This turns nuclear waste into a valuable resource, with nations like the UK holding significant stockpiles that can be reprocessed. For Europe, which has historically relied on the US or Russia for Pu-238, developing an Am-241 supply chain offers strategic independence and a more affordable path to space.

However, americium presents its own technical hurdles. It has a lower power density than plutonium, meaning more material is needed to generate the same amount of heat. It also emits low-energy gamma radiation, requiring additional shielding to protect sensitive instruments. The primary challenge, however, has been processing raw americium dioxide into a dense, stable, and safe fuel form—a ceramic pellet—that can be sealed within a power system and withstand the rigors of a rocket launch and the harsh environment of space. This is the problem that the Perpetual Atomics and QSA Global collaboration has now solved.

From Concept to Ceramic in One Year

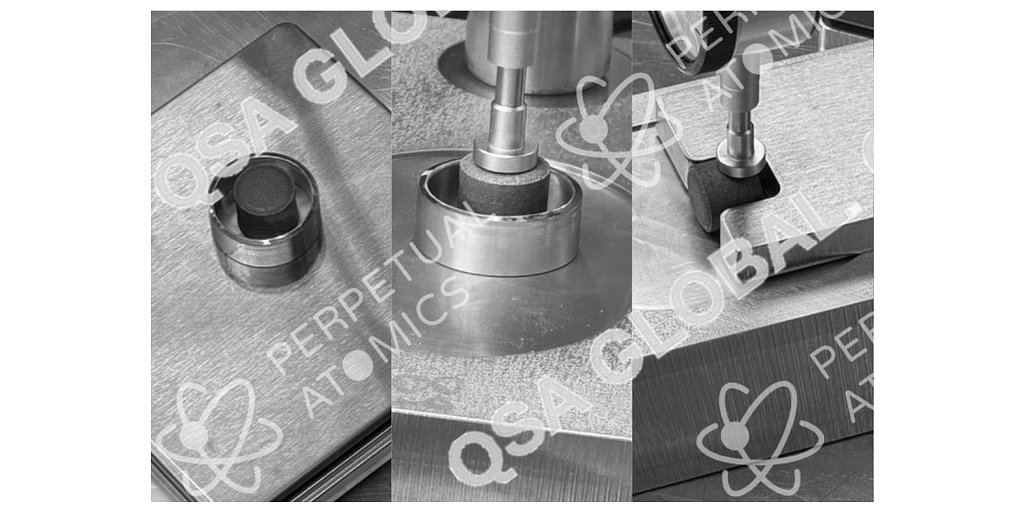

Leveraging a novel process not previously applied to americium, the joint UK-US team has produced the largest reported ceramic americium pellet of its kind. The new method is designed for industrial-scale production, a critical step in moving from laboratory theory to deployable hardware. The process creates high-density pellets that maximize power output while minimizing waste and production time, making it possible to tailor fuel sources for specific mission needs, such as the 3-watt thermal RHUs required to help lunar landers "survive the night."

Dr. Ramy Mesalam, Chief Technical Officer of Perpetual Atomics, highlighted the fusion of foundational science and practical engineering. “We are very excited about this development as it underscores the importance of the fundamental science and engineering required to develop new technologies, as well as the empirical nature of the challenge,” he commented. “Developing the fuel form and a stable processing method was the primary challenge and this was successfully addressed... in record time.”

The rapid progress is a testament to the synergy between the two companies. Perpetual Atomics, a spin-out from the University of Leicester, brings over 20 years of expertise in space nuclear systems, while QSA Global contributes decades of experience in manufacturing robust, sealed radioisotope sources for harsh industrial environments on Earth. “By combining Perpetual Atomics’ space nuclear power expertise with QSA Global’s decades of sealed source design, qualification, and high-reliability manufacturing, we’re turning a promising concept into real hardware,” said Dr. Joe Lapinskas, Director of Innovation and Marketing at QSA Global.

Professor Richard Ambrosi, Chief Scientific Officer of Perpetual Atomics, emphasized the historic nature of the achievement. “The speed of this development and its historic implications are significant. It is a testament to the world-leading capability, know-how, and focus that have enabled this success.”

Powering a New Era of Lunar and Deep Space Exploration

This technological advance is not happening in a vacuum. It directly supports the ambitious roadmaps of major space agencies. The European Space Agency (ESA) is targeting the late 2020s for lunar missions that will rely on Am-241-based power systems to explore and operate at the Moon’s frigid South Pole, an area of intense scientific interest. The ability to manufacture these fuel pellets at scale is the critical enabling step for such missions.

The UK Space Agency has been a vocal supporter of these efforts, recognizing the strategic importance of building a domestic capability in space nuclear power. “This is an exciting breakthrough that demonstrates the UK’s growing leadership in space nuclear power systems,” said Matthew Cook, Head of Space Exploration at the UK Space Agency. “By developing scalable americium fuel pelleting processes here in the UK, we’re ensuring British expertise remains at the forefront of this critical technology.”

The development is also a significant milestone for Space Park Leicester, the £100 million innovation hub where Perpetual Atomics is based. William Wells, the park's CEO, noted, “This is a fantastic example of how Space Park Leicester acts as a hub for space innovation and industry-academia collaboration.” By providing the essential infrastructure for both scientific research and industrial partnership, such innovation hubs are proving crucial in accelerating the journey from concept to cosmos. This transatlantic success story demonstrates how targeted collaboration can rapidly overcome long-standing technological barriers, paving the way for a new generation of robotic explorers ready to venture into the solar system’s most challenging frontiers.